ÿþM icrosoft W ord - 0 0 0 1 1 0 TOC . doc PDF

Preview ÿþM icrosoft W ord - 0 0 0 1 1 0 TOC . doc

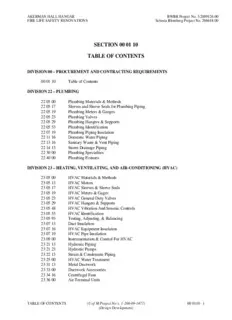

AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 SECTION 00 01 10 TABLE OFCONTENTS DIVISION00–PROCUREMENTANDCONTRACTINGREQUIREMENTS 000110 TableofContents DIVISION22–PLUMBING 220500 PlumbingMaterials&Methods 220517 SleevesandSleeveSealsforPlumbingPiping 220519 PlumbingMeters&Gauges 220523 PlumbingValves 220529 PlumbingHangers&Supports 220553 PlumbingIdentification 220719 PlumbingPipingInsulation 221116 DomesticWaterPiping 221316 SanitaryWaste&VentPiping 221413 StormDrainagePiping 223000 PlumbingSpecialties 224000 PlumbingFixtures DIVISION23–HEATING,VENTILATING,ANDAIR-CONDITIONING(HVAC) 230500 HVACMaterials&Methods 230513 HVACMotors 230517 HVACSleeves&SleeveSeals 230519 HVACMeters&Gages 230523 HVACGeneralDutyValves 230529 HVACHangers&Supports 230548 HVACVibrationAndSeismicControls 230553 HVACIdentification 230593 Testing,Adjusting,&Balancing 230713 DuctInsulation 230716 HVACEquipmentInsulation 230719 HVACPipeInsulation 230900 Instrumentation&ControlForHVAC 232113 HydronicPiping 232123 HydronicPumps 232213 Steam&CondensatePiping 232500 HVACWaterTreatment 233113 MetalDuctwork 233300 DuctworkAccessories 233416 CentrifugalFans 233600 AirTerminalUnits TABLEOFCONTENTS (UofMProjectNo’s.1-266-09-1477) 000110-1 (DesignDevelopment) AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 233713 Diffusers,RegistersandGrilles 233723 HVACGravityVentilators 234100 ParticulateAirFiltration 235700 HeatExchangersforHVAC 237314 FactoryCustomAirHandlingUnits 238239 UnitHeaters DIVISION26-ELECTRICAL 260500 CommonWorkResultsforElectrical 260019 Low-VoltageElectricalPowerConductorsandCables 260526 GroundingandBondingforElectricalSystems 260529 HangersandSupportsforElectricalSystems 260533 RacewayandBoxesforElectricalSystems 260536 CableTraysforElectricalSystems 260553 IdentificationforElectricalSystems 260923 LightingControlDevices 262200 Low-VoltageTransformers 262416 Panelboards 262726 WiringDevices 265100 InteriorLighting DIVISION27–COMMUNICATION NOTUSED DIVISION28–ELECTRONICSAFETYANDSECURITY 283111 Digital,AddressableFireAlarmSystem ENDOFDOCUMENT TABLEOFCONTENTS (UofMProjectNo’s.1-266-09-1477) 000110-2 (DesignDevelopment) AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 SECTION 22 0500 PLUMBINGMATERIALSAND METHODS PART 1- GENERAL 1.1 RELATEDDOCUMENTS A. Drawings and general provisions of the Contract, including General and Supplementary ConditionsandDivision1SpecificationSections,applytothisSection. 1.2 SUMMARY A. ThisSectionincludesthefollowing: 1. Buildingserviceoutages. 2. Electricalrequirementsforplumbingequipment. 3. Weldingrequirements. 4. Firesafetyprecautions 5. Plumbingsystemscommissioning 6. Pipingmaterialsandinstallationinstructionscommontomostpipingsystems. 7. Transitionfittings. 8. Dielectricfittings. 9. Escutcheons. 10. Grout. 11. CuttingandPatching 12. PlumbingDemolition 13. Equipmentinstallationrequirementscommontoequipmentsections. 14. Paintingandfinishing. 15. Concretebases. 16. Supportsandanchorages. 1.3 DEFINITIONS A. Finished Spaces: Spaces other than mechanical and electrical equipment rooms, furred spaces, pipe and duct shafts, unheated spaces immediately below roof, spaces above ceilings,unexcavatedspaces,crawlspaces,andtunnels. B. Exposed, Interior Installations: Exposed to view indoors. Examples include finished occupiedspacesandmechanicalequipmentrooms. C. Exposed, Exterior Installations: Exposedto view outdoors or subject to outdoor ambient temperaturesandweatherconditions. Examplesincluderooftoplocations. PLUMBINGMATERIALS& (UofMProjectNo’s.1-266-09-1477) 220500-1 METHODS (DesignDevelopment) AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 D. Concealed, Interior Installations: Concealed from view and protected from physical contactbybuildingoccupants. Examplesincludeaboveceilingsandinductshafts. E. Concealed, Exterior Installations: Concealed from view and protected from weather conditions and physical contact by building occupants but subject to outdoor ambient temperatures. Examplesincludeinstallationswithinunheatedshelters. F. Thefollowingareindustryabbreviationsforplasticmaterials: 1. ABS: Acrylonitrile-butadiene-styreneplastic. 2. CPVC: Chlorinatedpolyvinylchlorideplastic. 3. PE: Polyethyleneplastic. 4. PVC: Polyvinylchlorideplastic. G. Thefollowingareindustryabbreviationsforrubbermaterials: 1. EPDM: Ethylene-propylene-dieneterpolymerrubber. 2. NBR: Acrylonitrile-butadienerubber. 1.4 SUBMITTALS A. ProductData: Forthefollowing: 1. Transitionfittings. 2. Dielectricfittings. 3. Mechanicalsleeveseals. 4. Escutcheons. B. Weldingcertificates. 1.5 QUALITYASSURANCE A. ProductStandards: 1. RefertoDivision1. 2. Where products are specified by manufacturer, brand name or catalog number, this establishes the standard of quality and style of the product to be provided undertheContract,unlessachangeinqualityorstyleisapprovedbyOwner. 3. All Contractor-furnished equipment, including its component parts, shall be the current standard products of the manufacturer in order to insure prompt and continuingserviceandreplacementofparts. 4. Where 2 or more units of the same class of equipment are required, these units shall be the products of a single manufacturer; however, the component parts of theequipmentneednotbetheproductofthesamemanufacturer. B. ReferencedStandards: 1. The following are names of technical and trade organizations, together with the corresponding acronyms, used in this Specification when citing specific standardspublishedbytheseorganizations: PLUMBINGMATERIALS& (UofMProjectNo’s.1-266-09-1477) 220500-2 METHODS (DesignDevelopment) AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 a. Air-ConditioningandRefrigerationInstitute(ARI) b. AmericanConcreteInstitute c. AmericanConferenceofGovernmentalIndustrialHygienists d. AmericanGasAssociation(AGA) e. AmericanInstituteofSteelConstruction f. AmericanNationalStandardsInstitute(ANSI) g. American Society of Heating, Refrigeration and Air Conditioning Engineers h. AmericanSocietyofMechanicalEngineers(ASME) i. AmericanSocietyforTestingMaterials(ASTM) j. AmericanWaterWorksAssociation(AWWA) k. AmericanWeldingSociety l. ANSICodeforPowerPipingB31.1 m. Hydraulic Institute Standards for Centrifugal, Rotary and Reciprocating Pumps n. InstituteofElectricalandElectronicEngineers o. NationalBureauofStandards p. NationalCommercialandIndustrialInsulationStandards q. NationalElectricalManufacturersAssociation(NEMA) r. NationalElectricCode(NEC) s. NationalSafetyCodeforMechanicalRefrigeration t. OccupationalSafetyandHealthOrganization(OSHA) u. TubularExchangerManufacturersAssociation(TEMA) v. UnderwritersLaboratories(UL) 2. Where a reference standard is cited in this Specification, the subject to which it applies (equipment, material or work) shall be in compliance with the most recenteditionofthatstandard. 3. None of the above, however, shall be construed as relieving Contractor from complying with any requirement in this Specification that may be in excess of, butnotcontraryto,thereferencedstandard. 1.6 BUILDINGSERVICEOUTAGES A. ServiceOutageRequest:Thecontractorshallrequestallbuildingserviceoutagesthrough the owner’s representative. The contractor shall provide a minimum notification of 24 hours. PLUMBINGMATERIALS& (UofMProjectNo’s.1-266-09-1477) 220500-3 METHODS (DesignDevelopment) AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 1.7 ELECTRICALREQUIREMENTSFORPLUMBINGEQUIPMENT A. Equipment of higher electrical characteristics may be furnished provided such proposed equipment is approved inwritingand connectingelectrical services, circuit breakers, and conduit sizes are appropriately modified. If minimum energy ratings or efficiencies are specified,equipmentshallcomplywithrequirements. 1.8 WELDINGREQUIREMENTS A. Steel Support Welding: Qualify processes and operators according to AWSD1.1, "StructuralWeldingCode--Steel." 1.9 FIRESAFETYPRECAUTIONS A. AHotWorksPermitisrequiredforanytemporaryoperationthatinvolvesopenflamesor produces heat and/or sparks. Such operations include, but are not limited to, brazing cutting, grinding, soldering, thawing pipe, torch applied roofing, and welding. Before doing any type of open flame or hot works operation, obtain a Hot Works Permit from the customer service representative in the particular zone where the work will be performed. B. All grinding, cutting, brazing, sweating, or welding operations carried on in the vicinity of, or accessible to combustible material, shall be adequately protected to make certain thatasparkorhotslagdoesnotreachthecombustiblematerialandstartafire. C. When it is necessary to do grinding, cutting, brazing, sweating or welding close to wood construction in pipe shafts or other locations where combustible materials cannot be removed or adequately protected, employ fireproof blankets and proper fire extinguishers. Ahelpershallbestationednearbytoguardagainstsparksandfire. D. Whenever combustible material has been exposed to molten metal or hot slag from welding or cutting operations or spatter from electric arc, a fireguard shall be kept at the place of the hot workfor at least one hour after completion to make sure that smoldering firestonotstart. E. Whenweldingorcuttinginverticalpipeshaftorflooropening,afireguardshallexamine all floors belowthe weldingor cuttingoperation. Thefireguardshall be kept ondutyfor atleastonehouraftercompletionofworktoguardagainstfires. 1.10 DELIVERY,STORAGE,ANDHANDLING A. Deliver pipes and tubes with factory-applied end caps. Maintain end caps through shipping, storage, and handling to prevent pipe end damage and to prevent entrance of dirt,debris,andmoisture. B. Store plastic pipes protected from direct sunlight. Support to prevent sagging and bending. 1.11 COORDINATION A. Arrange for pipe spaces, chases,slots, andopenings inbuildingstructure duringprogress ofconstruction,toallowforplumbinginstallations. PLUMBINGMATERIALS& (UofMProjectNo’s.1-266-09-1477) 220500-4 METHODS (DesignDevelopment) AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 B. Coordinate installation of required supporting devices and set sleeves in poured-in-place concreteandotherstructuralcomponentsastheyareconstructed. C. Coordinate requirements for access panels and doors for mechanical items requiring accessthatareconcealedbehindfinishedsurfaces. Accesspanelsanddoorsarespecified inDivision8Section"AccessDoorsandFrames." 1.12 STARTUP/COMMISSIONING A. The building plumbing systems shall be commissioned in accordance with the latest edition of the ASHRAE document, “Guideline for Commissioning of Plumbing Systems”. Documentation and testing of these systems is required in cooperation with theCommissioningAuthority. Projectcloseoutisdependantonsuccessfulcompletionof all commissioning procedures, documentation, and issue closure. Refer to Project Closeout, Section 01700, for substantial completion details. Refer to Section 01810 for detailedcommissioningrequirements. B. For purposes of implementing this guideline, the Commissioning Authority shall be definedasbeingamemberoftheUniversityStaff. C. The contractor shall provide labor, material, and equipment required to facilitate the commissioning process as well as making adjustments and modifications needed to correctdeficienciesintheoperationoftheequipment. D. The contractor shall submit copies of the service tickets to the commissioning authority during the one-year correction period. This step verifies that there are no unresolved deficiencieswiththesystem. PART 2- PRODUCTS 2.1 MANUFACTURERS A. In other Part2 articles where subparagraph titles below introduce lists, the following requirementsapplyforproductselection: 1. Manufacturers: Subject to compliance with requirements, provide products by themanufacturersspecified. 2.2 PIPE,TUBE,ANDFITTINGS A. Refer to individual Division22 piping Sections for pipe, tube, and fitting materials and joiningmethods. B. PipeThreads: ASMEB1.20.1forfactory-threadedpipeandpipefittings. 2.3 JOININGMATERIALS A. Refer to individual Division22 piping Sections for special joining materials not listed below. B. Pipe-Flange Gasket Materials: Suitable for chemical and thermal conditions of piping systemcontents. PLUMBINGMATERIALS& (UofMProjectNo’s.1-266-09-1477) 220500-5 METHODS (DesignDevelopment) AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 1. ASMEB16.21, nonmetallic, flat, asbestos-free, 1/8-inch maximum thickness unlessthicknessorspecificmaterialisindicated. a. Full-Face Type: For flat-face, Class125, cast-iron and cast-bronze flanges. b. Narrow-Face Type: For raised-face, Class250, cast-iron and steel flanges. 2. AWWAC110, rubber, flat face, 1/8 inch thick, unless otherwise indicated; and full-faceorringtype,unlessotherwiseindicated. C. FlangeBoltsandNuts: ASMEB18.2.1,carbonsteel,unlessotherwiseindicated. D. Plastic,Pipe-Flange Gasket,Bolts,andNuts: Type andmaterialrecommendedbypiping systemmanufacturer,unlessotherwiseindicated. E. Solder Filler Metals: ASTMB32, lead-free alloys. Include water-flushable flux accordingtoASTMB813. F. Brazing Filler Metals: AWSA5.8, BCuPSeries, copper-phosphorus alloys for general- duty brazing, unless otherwise indicated; and AWSA5.8, BAg1, silver alloy for refrigerantpiping,unlessotherwiseindicated. G. WeldingFiller Metals: Comply with AWSD10.12 for welding materials appropriate for wallthicknessandchemicalanalysisofsteelpipebeingwelded. H. SolventCementsforJoiningPlasticPiping: 1. ABSPiping: ASTMD2235. 2. CPVCPiping: ASTMF493. 3. PVCPiping: ASTMD2564. IncludeprimeraccordingtoASTMF656. 4. PVCtoABSPipingTransition: ASTMD3138. 2.4 TRANSITIONFITTINGS A. AWWA Transition Couplings: Same size as, and with pressure rating at least equal to andwithendscompatiblewith,pipingtobejoined. 1. Manufacturers: a. CascadeWaterworksMfg.Co. b. DresserIndustries,Inc.;DMDDiv. c. FordMeterBoxCompany,Incorporated(The);PipeProductsDiv. d. JCMIndustries. e. Smith-Blair,Inc. f. VikingJohnson. 2. UndergroundPipingNPS1-1/2andSmaller: Manufacturedfittingorcoupling. 3. Underground Piping NPS2 and Larger: AWWAC219, metal sleeve-type coupling. PLUMBINGMATERIALS& (UofMProjectNo’s.1-266-09-1477) 220500-6 METHODS (DesignDevelopment) AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 4. AbovegroundPressurePiping: Pipefitting. B. Plastic-to-Metal Transition Fittings: CPVC and PVC one-piece fitting with manufacturer's Schedule80 equivalent dimensions; one end with threaded brass insert, andonesolvent-cement-jointend. 1. Manufacturers: a. EslonThermoplastics. C. Plastic-to-Metal Transition Adaptors: One-piece fitting with manufacturer's SDR11 equivalent dimensions; one end with threaded brass insert, and one solvent-cement-joint end. 1. Manufacturers: a. ThompsonPlastics,Inc. D. Plastic-to-Metal Transition Unions: MSSSP-107, CPVC and PVC four-part union. Includebrassend,solvent-cement-jointend,rubberO-ring,andunionnut. 1. Manufacturers: a. NIBCOINC. b. NIBCO,Inc.;ChemtrolDiv. E. Flexible Transition Couplings for Underground Nonpressure Drainage Piping: ASTMC1173 with elastomeric sleeve, ends same size as piping to be joined, and corrosion-resistantmetalbandoneachend. 1. Manufacturers: a. CascadeWaterworksMfg.Co. b. Fernco,Inc. c. MissionRubberCompany. d. PlasticOddities,Inc. 2.5 DIELECTRICFITTINGS A. Description: Combination fitting of copper alloy and ferrous materials with threaded, solder-joint,plain,orweld-neckendconnectionsthatmatchpipingsystemmaterials. B. InsulatingMaterial: Suitableforsystemfluid,pressure,andtemperature. C. Dielectric Unions: Factory-fabricated, union assembly, for 250-psig minimum working pressureat180degF. 1. Manufacturers: a. CapitolManufacturingCo. b. CentralPlasticsCompany. c. Eclipse,Inc. d. EpcoSales,Inc. PLUMBINGMATERIALS& (UofMProjectNo’s.1-266-09-1477) 220500-7 METHODS (DesignDevelopment) AKERMANHALLHANGAR BWBRProjectNo.3.2009126.00 FIRELIFESAFETYRENOVATIONS SebestaBlombergProjectNo.206618.00 e. HartIndustries,International,Inc. f. WattsIndustries,Inc.;WaterProductsDiv. g. ZurnIndustries,Inc.;WilkinsDiv. D. Dielectric Flanges: Factory-fabricated,companion-flange assembly,for 150-or 300-psig minimumworkingpressureasrequiredtosuitsystempressures. 1. Manufacturers: a. CapitolManufacturingCo. b. CentralPlasticsCompany. c. EpcoSales,Inc. d. WattsIndustries,Inc.;WaterProductsDiv. E. Dielectric-Flange Kits: Companion-flange assemblyfor fieldassembly. Include flanges, full-face-orring-typeneopreneorphenolicgasket,phenolicorpolyethyleneboltsleeves, phenolicwashers,andsteelbackingwashers. 1. Manufacturers: a. AdvanceProducts&Systems,Inc. b. Calpico,Inc. c. CentralPlasticsCompany. d. PipelineSealandInsulator,Inc. 2. Separate companion flanges and steel bolts and nuts shall have 150- or 300-psig minimumworkingpressurewhererequiredtosuitsystempressures. F. Dielectric Couplings: Galvanized-steel coupling with inert and noncorrosive, thermoplastic lining; threaded ends; and 300-psig minimum working pressure at 225 degF. 1. Manufacturers: a. Calpico,Inc. b. LochinvarCorp. G. Dielectric Nipples: Electroplated steel nipple with inert and noncorrosive, thermoplastic lining; plain, threaded, or grooved ends; and 300-psig minimum working pressure at 225 degF. 1. Manufacturers: a. PerfectionCorp. b. PrecisionPlumbingProducts,Inc. c. SiouxChiefManufacturingCo.,Inc. d. VictaulicCo.ofAmerica. PLUMBINGMATERIALS& (UofMProjectNo’s.1-266-09-1477) 220500-8 METHODS (DesignDevelopment)