Wooden boxes PDF

Preview Wooden boxes

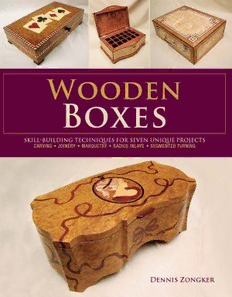

Wooden Boxes Skill-BuilDing TechniqueS for Seven unique ProjecTS Carving ◆ Joinery ◆ Marquetry ◆ radius inlays ◆ segMented turning Dennis Zongker D e n n i s z o n g k e r Wooden Boxes t Text © 2013 by Dennis Zongker Photographs © 2013 by The Taunton Press, Inc. Illustrations © 2013 by The Taunton Press, Inc. All rights reserved. Pp The Taunton Press, Inc., 63 South Main Street, PO Box 5506, Newtown, CT 06470-5506 e-mail: [email protected] Editor: Joseph Truini Copy Editor: Candace B. Levy Indexer: Barbara Mortenson Jacket/Cover design: Rita Sowins Interior design: Kimberly Adis Layout: David Giammattei Illustrator: Christopher Mills Photographer: Dennis Zongker Library of Congress Cataloging-in-Publication Data Zongker, Dennis Lee. Wooden boxes : skill building techniques for seven unique projects / Dennis Lee Zongker. pages cm E-Book ISBN 978-1-62710-347-3 1. Wooden boxes. 2. Ornamental boxes. 3. Woodwork. 4. Box making. I. Title. TT200.Z66 2013 745.51--dc23 Printed in the United States of America 10 9 8 7 6 5 4 3 2 1 The following names/manufacturers appearing in Wooden Boxes are trademarks: Delta®, DeVilbiss®, Forstner®, Gorilla Tape®, M.L. Campbell®, Magnalac®, Mohawk®, NOVA™, Olson®, Stanley Surform®, Titebond®, Tormek®, Ultra® Working with wood is inherently dangerous. Using hand or power tools improperly or ignoring safety practices can lead to permanent injury or even death. Don’t try to perform operations you learn about here (or elsewhere) unless you’re certain they are safe for you. If something about an operation doesn’t feel right, don’t do it. Look for another way. We want you to enjoy the craft, so please keep safety foremost in your mind whenever you’re in the shop. To the loving memory of my mother, Shirley, who never had a chance to see me complete this book. No matter what I made, whether it turned out good or not so good, she would always love it just the same. I will truly miss all her encouragement, love, and support. And also in loving memory of my sister Debbie, whose life was cut short. Thank you for always being there with a smile on your face. acknowledgments A lot of pAssion, work, And devotion went into completing this book, but every moment was well worth the journey to get here. This book would not have been possible without a great deal of help from many people. I’d like to express my sincere gratitude to those who have helped me along the way. To my wife, Patti, I’d like to give a special thank you for all her many hours of helping design boxes, pushing the camera shutter, and editing the chapters, but mostly for always believing in me. And thanks to her daughter, Theresa, for drawing the beautiful roses that adorn the Traditional Jewelry Box. A very special thank you to Peter Chapman, Executive Editor at The Taunton Press, for all the hard work that went into taking my ideas, putting them together, and making this book a reality. Thanks for giving me the chance to write this book. Thank you to Ed Pirnik, of Fine Woodworking magazine, for introducing my book idea to the book department at The Taunton Press. And thanks, too, to the designer, copyeditor, illustrator, photo editor, and layout and marketing people at The Taunton Press, each of whom played a key role in bringing the book together. Last, but not least, thanks to Joseph Truini, my editor, for making sense out of my complex explanations and for helping a woodworker become a writer. Thank you, Joe, for all that you have taught me along the way. And a special mention to my son, Eric: May this book take your woodworking to a new level and give you the inspiration to always strive to be your best and to never stop wanting to improve. Contents 2 Introduction 4 Serpentine Coin Box 38 Playing Card Box 6 Cut the hardwood parts 40 Make the banding 7 Cut and veneer the box top and bottom 45 Window method of marquetry 9 Cut the miters and rabbets 50 Make the box bottom 10 Cut the bottom groove and rabbet 51 Cut the bottom groove 11 Lay out the serpentine front 51 Rout the box miters 12 Cut the serpentine front 53 Cut the box in half 14 Rout the corner dovetails 54 Veneer the edges 14 Make the dovetail splines 55 Rout rabbets for the banding 15 Glue the box together 57 Install the hinges 16 Veneer the box top 58 Make the box feet 17 Make a serpentine caul 58 Turn the knob 18 Cut the box veneer 60 Cut the interior dividers 20 Cut the box in half 21 Cut rabbets for the ebony banding 62 Artist Sketch Box 22 Cut the ebony banding 64 Cut the hardwood and plywood box parts 26 Cut the base parts 70 Cut the pencil-tray parts 27 Shape and assemble the base 72 Glue the box together 28 Turn the bun feet 74 Make the decorative banding 30 Install a full-mortise lockset 75 Veneer the decorative side panels 33 Install the hinges 78 Glue on the veneered end panels 34 Make the coin trays 80 Cut the top veneer panel 36 Apply the finish 81 Make the Greek key banding 37 Install the tray liners 85 Cut the rabbet and the corner banding 87 Cut the box in half 89 Make the interior panels 92 Make the inside cleat and support blocks 168 Veneer the outside surfaces 94 Install the hinges 172 Glue the box together 94 Attach the catches and handle 174 Prepare the outside corners 95 Finish the box 175 Veneer the top edges 176 Make the box top 96 Music Box 177 Veneer the box top 179 Rout the cameo marquetry recess 98 Veneer the hardwood parts 180 Glue the cameo marquetry to the box top 100 Lay out and cut the box parts 182 Make the elliptical inlay 106 Glue the box together 185 Veneer the box top edges 107 Veneer the top edges 186 Create a finger pull 108 Construct the inner box 187 Make the inside dividers 110 Install the radius trim block 111 Fabricate the decorative trim with inlay 188 Traditional Jewelry Box 117 Install the trim 118 Make the segmented feet blank 191 Make the bottom platform 123 Veneer the box top 194 Veneer the lower box parts 125 Attach trim to the box top 195 Fabricate the back and back base 126 Rout the box top 197 Cut the mitered base trim 126 Make the lyre harp 200 Make the two box ends 129 Install the hinges 202 Make the drawer slides 129 Finish the music box 203 Make the fronts, corners, and return corners 207 Make the upper tray sides 130 Rose Box 209 Veneer the edges 210 Make the tray bottoms 132 Prep the parts for glue-up 211 Turn the maple columns 134 Cut and glue the ebony accent pieces 212 Start assembling the box 135 Cut the miter joints 213 Mill the maple accent trim 137 Shape the front, back, and ends 214 Make the radius doors 139 Cut the box top and bottom 215 Select and cut veneers 140 Assemble the box 218 Nail and rivet the veneer packets 142 Prepare the center medallion 219 Cut the veneer packet 145 Shape the top 223 Glue the marquetry to the door 147 Stab-cut the roses onto the top and front 224 Make and attach the door pulls 152 Rout the top for ebony trim 226 Build the drawers 156 Install the hinges 229 Make the box top 157 Finishing touches 231 Install the door hinges 231 Install the door catches 158 Cameo Jewelry Box 232 Install the box top hinges 160 Cut the hardwood box parts 232 Finishing and flocking 164 Rout for the splines and bottom 233 Mount the chain carousels 165 Cut the bottom profiles 167 Veneer the inside surfaces 235 Metric Equivalents 2 introduction box mAking hAs been Around since the box making. Taking a mixture of the different styles time of the ancient Egyptians, and it’s still one of can help in the design and building of a box of your the most popular pastimes for modern-day wood- own design. workers. Boxes can be made for all kinds of reasons: This book is for all woodworkers who are look- keeping playing cards, coins, and art supplies in ing for a new challenge. It’s about teaching different order; protecting jewelry; storing wine; and playing woodworking techniques in joinery, different styles music, to name but a few. They can also be made of cutting marquetry, perfecting radius inlays, and just for decoration. making your own diamond-pattern banding, to Today, boxes are handcrafted by professional name just a few skills. It’s also filled with informa- woodworkers and hobbyists alike. They range from tion that will surely come in handy when working simple unadorned boxes to the most elaborate on your next box. designs imaginable by any craftsman. Each custom- I’ll walk you through from the simplest box to built wooden box is unique and slightly different some more-complex designs. Working on each one from any other. Box making has grown in popularity of these boxes and coming up with new designs has due to creativity and the joy of producing some- been a rewarding challenge for me. Being innova- thing that has never been done before. tive can change the basic square box into a creative Over the past few years I have developed a strong design. As when learning anything new, you start passion for box making, and seeing all the ways a simple and once you have mastered that you move box can be designed has opened my mind to being on to more complex boxes with more detailed more creative. When designing boxes I want them designs. That’s what I show throughout this book to be a pleasure to look at, with carvings and color- with each box, starting easy and working to the ful marquetry, but also to be pleasurable to listen to more difficult. The techniques you’ll learn can be with music. My boxes often have unique features, applied to many types of projects, not just for mak- such as segmented turnings, decorative trim, and ing these unique boxes. Use them for almost any even serpentine radius fronts that make them stand type of woodworking project. out from basic boxes. I have thoroughly enjoyed sharing my wood- When designing each one of the seven boxes working style and techniques with others, and I shown in this book, I did a lot of research and used hope I can help you explore new and many more plenty of trial and error to ensure the best outcome possibilities. We all have to start somewhere, and for each one. I wanted to be able to add as many dif- with a little determination and enthusiasm, these ferent techniques to build the reader’s skill from the newfound skills can open the world to creating any- beginning techniques to the more difficult levels of thing your mind can imagine. 3 Serpentine Coin Box wanted this box to be I as beautiful on the inside as it is on the outside, so I combined quilted bubinga hardwood with chest- nut burl veneer for a strikingly elegant look. As a complementary touch, and also to provide protection, I added solid ebony to all outside edges. The serpentine front has a convex curve in the center flanked by slightly con- cave ends. The box interior has three removable coin trays made from quilted bubinga, a hardwood with rich, reddish tones that will highlight your prized coin collection. In this chapter, you’ll learn how to make the three-radius serpentine box front using a bandsaw. There are also techniques on making dovetail splines that join the mitered corners on both the box and the coin trays. Splined- dovetail joints are highly decorative but are also very strong and durable. I show how to install small brass knobs for lifting and stacking the coin trays, which fit snugly within the box. And there are also detailed instructions for installing a full-mortise lock for keeping your coin collection Finished size of box: 61⁄8 in. tall 93⁄4 in. deep 14 in. wide secure. 4 Serpentine Coin Box materials Quantity Part size ConstruCtion notes 1 Front 17⁄8 in. 51⁄8 in. 14 in. quilted bubinga 1 Back 5⁄8 in. 51⁄8 in. 14 in. quilted bubinga 2 Ends 5⁄8 in. 51⁄8 in. 81⁄2 in. quilted bubinga 1 Top 1⁄2 in. 81⁄2 in. 14 in. maple plywood 1 Bottom 1⁄2 in. 73⁄4 in. 131⁄4 in. maple plywood 1 Inside top veneer 1⁄42 in. 83⁄4 in. 141⁄4 in. bubinga burl veneer 2 Bottom veneer 1⁄42 in. 8 in. 131⁄2 in. bubinga burl veneer 1 Dovetail spline material 5⁄16 in. 3⁄8 in. 36 in. black ebony 1 Top veneer 1⁄42 in. 11 in. 141⁄2 in. maple veneer 1 Top veneer (exterior) 1⁄42 in. 10 in. 141⁄4 in. chestnut burl veneer 1 Back veneer (exterior) 1⁄42 in. 53⁄8 in. 141⁄4 in. chestnut burl veneer 1 Front veneer (exterior) 1⁄42 in. 53⁄8 in. 143⁄4 in. chestnut burl veneer 2 End veneer (exterior) 1⁄42 in. 53⁄8 in. 83⁄4 in. chestnut burl veneer 22 Banding 3⁄16 in. 3⁄16 in. 18 in. black ebony 1 Bottom base front 1⁄2 in. 31⁄2 in. 17 in. quilted bubinga 1 Bottom base back 1⁄2 in. 11⁄4 in. 15 in. quilted bubinga 2 Bottom base ends 1⁄2 in. 15⁄8 in. 10 in. quilted bubinga 4 Splines 1⁄4 in. 3⁄4 in. 11⁄8 in. any hardwood 4 Bun feet 17⁄16 in. 17⁄16 in. 1 in. black ebony 1 Full-mortise box lock brass 1 Escutcheon 1⁄8 in. 1 in. 3 in. quilted bubinga 1 pair 95º stop hinges 11⁄16 in. 11⁄4 in. brass-plated 6 Small knobs 1⁄4 in. tall 5⁄16 in. dia. brass ▲▲ Serpentine Coin Box 5