US EPA, Pesticide Product Label, Anarchy 70 WP Insecticide,09/13/2016 PDF

Preview US EPA, Pesticide Product Label, Anarchy 70 WP Insecticide,09/13/2016

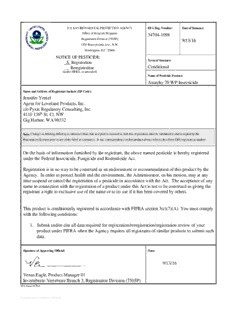

U.S. ENVIRONMENTAL PROTECTION AGENCY EPA Reg. Number: Date of Issuance: Office of Pesticide Programs 34704-1098 Registration Division (7505P) 9/13/16 1200 Pennsylvania Ave., N.W. Washington, D.C. 20460 NOTICE OF PESTICIDE: Term of Issuance: X Registration Reregistration Conditional (under FIFRA, as amended) Name of Pesticide Product: Anarchy 70 WP Insecticide Name and Address of Registrant (include ZIP Code): Jennifer Yentel Agent for Loveland Products, Inc. c/o Pyxis Regulatory Consulting, Inc. 4110 136th St. Ct. NW Gig Harbor, WA 98332 Note: Changes in labeling differing in substance from that accepted in connection with this registration must be submitted to and accepted by the Registration Division prior to use of the label in commerce. In any correspondence on this product always refer to the above EPA registration number. On the basis of information furnished by the registrant, the above named pesticide is hereby registered under the Federal Insecticide, Fungicide and Rodenticide Act. Registration is in no way to be construed as an endorsement or recommendation of this product by the Agency. In order to protect health and the environment, the Administrator, on his motion, may at any time suspend or cancel the registration of a pesticide in accordance with the Act. The acceptance of any name in connection with the registration of a product under this Act is not to be construed as giving the registrant a right to exclusive use of the name or to its use if it has been covered by others. This product is conditionally registered in accordance with FIFRA section 3(c)(7)(A). You must comply with the following conditions: 1. Submit and/or cite all data required for registration/reregistration/registration review of your product under FIFRA when the Agency requires all registrants of similar products to submit such data. Signature of Approving Official: Date: 9/13/16 Venus Eagle, Product Manager 01 Invertebrate-Vertebrate Branch 3, Registration Division (7505P) EPA Form 8570-6 Registration Notice Conditional v.20150320 Page 2 of 2 EPA Reg. No. 34704-1098 Decision No. 516828 2. You are required to comply with the data requirements described in the DCI identified below: a. Acetamiprid GDCI-099050-1300 You must comply with all of the data requirements within the established deadlines. If you have questions about the Generic DCI listed above, you may contact the Chemical Review Manager in the Pesticide Reevaluation Division: http://www.epa.gov/oppsrrd1/contacts_prd.htm 3. The data requirements for storage stability and corrosion characteristics (Guidelines 830.6317 and 830.6320) are not satisfied. A one year study is required to satisfy these data requirements. You have 18 months from the date of registration to provide these data. 4. Make the following label changes before you release the product for shipment: Revise the EPA Registration Number to read, “EPA Reg. No. 34704-1098.” 5. Submit one copy of the final printed label for the record before you release the product for shipment. Should you wish to add/retain a reference to the company’s website on your label, then please be aware that the website becomes labeling under the Federal Insecticide Fungicide and Rodenticide Act and is subject to review by the Agency. If the website is false or misleading, the product would be misbranded and unlawful to sell or distribute under FIFRA section 12(a)(1)(E). 40 CFR 156.10(a)(5) list examples of statements EPA may consider false or misleading. In addition, regardless of whether a website is referenced on your product’s label, claims made on the website may not substantially differ from those claims approved through the registration process. Therefore, should the Agency find or if it is brought to our attention that a website contains false or misleading statements or claims substantially differing from the EPA approved registration, the website will be referred to the EPA’s Office of Enforcement and Compliance. If you fail to satisfy these data requirements, EPA will consider appropriate regulatory action including, among other things, cancellation under FIFRA section 6(e). Your release for shipment of the product constitutes acceptance of these conditions. A stamped copy of the label is enclosed for your records. Please also note that the record for this product currently contains the following CSFs: Basic CSF dated 04/29/2016 If you have any questions, please contact Jessica Rogala by phone at 703-347-0263, or via email at [email protected]. Sep 13, 2016 [Note to reviewer: [Text] in brackets indicates optional text]. Anarchy 70 WP Insecticide 34704-1098 For Agricultural Use Only GROUP 4A INSECTICIDE ACTIVE INGREDIENT: By Wt. Acetamiprid, (E)-N1–[(6-chloro-3-pyridyl)methyl]-N2-cyano- N1-methyl acetamidine ............................................................................................................. 70.0% OTHER INGREDIENTS: .......................................................................................................... 30.0% TOTAL: .................................................................................................................................. 100.0% Contains acetamiprid, the active ingredient used in Assail® 70 WP Insecticide. Anarchy 70 WP Insecticide is not manufactured, or distributed by United Phosphorus, Inc., seller of Assail® 70 WP Insecticide. KEEP OUT OF REACH OF CHILDREN CAUTION Si usted no entiende la etiqueta, busque a alguien para que se la explique a usted en detalle. (If you do not understand the label, find someone to explain it to you in detail.) See inside label booklet for additional Precautionary Statements and Directions for Use including Storage and Disposal instructions. For help with any spill, leak, fire or exposure involving this material, call day or night CHEMTREC – 1-800-424-9300. EPA Reg. No. 34704-xx EPA Est. No. NET WEIGHT: Manufactured for: Loveland Products, Inc. P.O. Box 1286 Greeley, CO 80632-1286 Batch Code: 1 FIRST AID If swallowed: (cid:120) Immediately call a poison control center or doctor for treatment advice. (cid:120) Do not induce vomiting unless told to do so by a poison control center or doctor. (cid:120) Have person sip a glass of water if able to swallow. (cid:120) Do not give anything by mouth to an unconscious person. If in eyes: (cid:120) Hold eye open and rinse slowly and gently with water for 15-20 minutes. (cid:120) Remove contact lenses, if present, after the first 5 minutes, then continue rinsing. (cid:120) Call a poison control center or doctor for treatment advice. If on skin or (cid:120) Take off contaminated clothing. clothing: (cid:120) Rinse skin immediately with plenty of water for 15-20 minutes. (cid:120) Call a poison control center or doctor for treatment advice. If inhaled: (cid:120) Move person to fresh air. (cid:120) If person is not breathing, call 911 or an ambulance, then give artificial respiration, preferably mouth-to-mouth, if possible. (cid:120) Call a poison control center or doctor for treatment advice. HOT LINE NUMBER Have the product container or label with you when calling a poison control center or doctor, or going for treatment. You may also contact 1-866-944-8565 for emergency medical treatment information. NOTE TO PHYSICIAN: There is no specific antidote. All treatment should be based on observed signs and symptoms of distress in the patient. PRECAUTIONARY STATEMENTS HAZARDS TO HUMANS AND DOMESTIC ANIMALS CAUTION Harmful if swallowed or absorbed through skin. Causes moderate eye irritation. Avoid contact with eyes, skin or clothing. Harmful if inhaled. Avoid breathing vapors or spray mist. PERSONAL PROTECTIVE EQUIPMENT (PPE) Mixers, loaders, applicators, and other handlers must wear long-sleeved shirts, long pants, shoes plus socks, protective eyewear, chemical resistant gloves made out of the following waterproof materials (nitrile rubber ≥ 14 mils, neoprene rubber ≥ 14 mils, barrier laminate ≥ 14 mils, polyvinyl chloride (PVC) ≥ 14 mils, or viton ≥ 14 mils) and chemical resistant headgear for overhead exposure. In addition to the above, for aerial applications, mixers and loaders must wear a filtering face piece, half piece, or full face NIOSH approved particulate respirator (TC-84A) with any R or P filter. Discard clothing and other absorbent materials that have been drenched or heavily contaminated with this product’s concentrate. Do not reuse them. Follow manufacturer’s instructions for cleaning/maintaining PPE. If there are no such instructions for washables, use detergent and hot water. Keep and wash PPE separately from other laundry. When handlers use closed systems, enclosed cabs, or aircraft in a manner that meets the requirements listed in the Worker Protection Standard (WPS) for agricultural pesticides [40 CFR 170.240 (d)(4-6)], the handler PPE requirements may be reduced or modified as specified in the WPS. USER SAFETY RECOMMENDATIONS Users should: (cid:120) Wash hands before eating, drinking, chewing gum, using tobacco or using the toilet. (cid:120) Remove clothing/PPE immediately if pesticide gets inside. Then wash thoroughly and put on clean clothing. (cid:120) Remove PPE immediately after handling this product; wash the outside of gloves before removing. As soon as possible, wash thoroughly and change into clean clothing. 2 ENVIRONMENTAL HAZARDS This product is toxic to birds and aquatic invertebrates. This product is toxic to bees exposed to direct treatment. Do not apply this product while bees are foraging in the treatment area. Do not apply directly to water, or to areas where surface water is present, or to intertidal areas below the mean high water mark. Do not contaminate water when disposing of equipment washwater or rinsate. Do not contaminate water used for irrigation or domestic purposes. Ground Water Advisory This chemical has properties and characteristics associated with chemicals detected in ground water. This chemical may leach into ground water if used in areas where soils are permeable, particularly where the water table is shallow. Surface Water Advisory This product may impact surface water quality due to runoff of rain water. This is especially true for poorly draining soils and soils with shallow ground water. This product is classified as having high potential for reaching surface water via runoff for several months or more after application. Avoid accidental or intentional application of this product to ditches, swales, drainage ways or impervious surfaces such as driveways. Runoff of this product to surface water will be reduced by avoiding applications when rainfall is forecasted to occur within 48 hours. PHYSICAL OR CHEMICAL HAZARDS Do not mix or allow to come into contact with oxidizing agents. Hazardous chemical reaction may occur. DIRECTIONS FOR USE It is a violation of Federal law to use this product in any manner inconsistent with its labeling. Read entire label before using this product. Do not apply this product in a way that will contact workers or other persons, either directly or through drift. Only protected handlers may be in the area during application. For any requirements specific to your State or Tribe, consult the agency responsible for pesticide regulation. AGRICULTURAL USE REQUIREMENTS Use this product only in accordance with its labeling and with the Worker Protection Standard, 40 CFR part 170. This standard contains requirements for the protection of agricultural workers on farms, forests, nurseries, and greenhouses, and handlers of agricultural pesticides. It contains requirements for training, decontamination, notification, and emergency assistance. It also contains specific instructions and exceptions pertaining to the statements on this label about personal protective equipment (PPE) and restricted-entry intervals. The requirements in this box only apply to uses of this product that are covered by the Worker Protection Standard. Do not enter or allow worker entry into treated areas during the restricted entry interval (REI) of 12 hours. PPE required for early entry to treated areas that is permitted under the Worker Protection Standard and that involves contact with anything that has been treated, such as plants, soil, or water, is coveralls, waterproof gloves and shoes plus socks. SPRAY DRIFT Weather and equipment are the predominant factors in determining spray drift, and applications must not be made when weather conditions or equipment settings/function may lead to drift outside of the intended application area. Use nozzle and pressure combinations that distribute MEDIUM spray droplets (see nozzle manufacturer’s catalogs and ASAE Standard S-572) when applying this product by air. Aerial applications must NOT be made during temperature inversions or when wind speed is greater than 10 mph in order to avoid spray drift. The applicator is responsible for preventing spray drift from the target area. The interaction of many equipment- and weather-related factors determines the potential for spray drift. The applicator is responsible for considering all of these factors when making decisions. 3 The following drift management requirements must be followed to avoid off-target movement from aerial applications to agricultural crops. These requirements do not apply to forestry application, public health uses or to application using dry formulations. 1. The distance of the outer most nozzles on the boom must not exceed 3/4 the length of the wingspan or rotor. 2. Use the largest droplet size consistent with good pest control. Small droplets are more prone to spray drift and can be minimized by appropriate nozzle selection, by orienting nozzles away from the airstream as much as possible, and by avoiding excessive spray boom pressure. Where states have more stringent regulations, they should be observed. The applicator should be familiar with and take into account the information covered in the Aerial Drift Reduction Advisory below: AERIAL DRIFT REDUCTION ADVISORY [This section is advisory in nature and does not supersede the mandatory label requirements]. INFORMATION ON DROPLET SIZE The most effective way to reduce drift potential is to apply MEDIUM droplets. The best drift management strategy is to apply the largest droplets that provide sufficient coverage and control. Applying larger droplets reduces drift potential, but will not prevent drift if applications are made improperly, or under unfavorable environmental conditions (See Wind, Temperature and Humidity, and Temperature Inversions). CONTROLLING DROPLET SIZE Volume – Use high flow rate nozzles to apply the highest practical spray volume. Nozzles with higher rated flows produce larger droplets. Pressure – Do not exceed the nozzle manufacturer’s recommended pressures. For many nozzle types lower pressure produces larger droplets. When higher flow rates are needed, use higher flow rate nozzles instead of increasing pressure. Number of Nozzles – Use the minimum number of nozzles that provide uniform coverage. Nozzle Orientation – Small droplets are more prone to spray drift and can be minimized by several factors including orienting nozzles away from the airstream. Orienting nozzles so that the spray is released parallel to the airstream produces larger droplets than other orientations. Significant deflection from horizontal will reduce droplet size and increase drift potential. Nozzle Type – Use a nozzle type that is designed for the intended application. With most nozzle types, narrower spray angles produce larger droplets. Consider using low-drift nozzles. Solid stream nozzles oriented straight back produce the largest droplets and the lowest drift. BOOM LENGTH For some use patterns, reducing the effective boom length to less than 3/4 of the wingspan or rotor length may further reduce drift without reducing swath width. APPLICATION HEIGHT Applications should not be made at a height greater than 10 feet above the top of the target plants unless a greater height is required for aircraft safety. Making applications at the lowest height that is safe reduces exposure of droplets to evaporation and wind. SWATH ADJUSTMENT When applications are made with a crosswind, the swath will be displaced downwind. Therefore, on the up and downwind edges of the field, the applicator should compensate for this displacement by adjusting the path of the aircraft upwind. Swath adjustment distance should increase, with increasing drift potential (higher wind, smaller drops, etc.). WIND Drift potential is lowest between wind speeds of 2 – 10 mph. However, many factors, including droplet size and equipment type determine drift potential at any given speed. Application should be avoided below 2 4 mph due to variable wind direction and high inversion potential. NOTE: Local terrain can influence wind patterns. Every applicator should be familiar with local wind patterns and how they affect spray drift. TEMPERATURE AND HUMIDITY When making applications in low relative humidity, set up equipment to produce larger droplets to compensate for evaporation. Droplet evaporation is most severe when conditions are both hot and dry. TEMPERATURE INVERSIONS Applications should not occur during a temperature inversion because drift potential is high. Temperature inversions restrict vertical air mixing, which causes small suspended droplets to remain in a concentrated cloud. This cloud can move in unpredictable directions due to the light variable winds common during inversions. Temperature inversions are characterized by increasing temperatures with altitude and are common on nights with limited cloud cover and light to no wind. They begin to form as the sun sets and often continue into the morning. Their presence can be indicated by ground fog; however, if fog is not present, inversions can also be identified by the movement of smoke from a ground source or an aircraft smoke generator. Smoke that layers and moves laterally in a concentrated cloud (under low wind conditions) indicates an inversion, while smoke that moves upward and rapidly dissipates indicates good vertical air mixing. SENSITIVE AREAS The pesticide should only be applied when the potential for drift to adjacent sensitive areas (e.g. residential areas, bodies of water, know habitat for threatened or endangered species, non-target crops) is minimal (e.g. when wind is blowing away from the sensitive areas). Do not cultivate or plant crops within 10 feet of aquatic areas as to allow growth of a vegetative filter strip. DIRECTIONS FOR CHEMIGATION Instructions For chemigation use only on cranberries and on potatoes after foliage has emerged and only through overhead sprinkler irrigation systems. Apply this product only through overhead sprinkler irrigation systems including center pivot, lateral move, side (wheel) roll, solid set, or hand move irrigation systems after potato foliage has emerged. Do not apply this product through any other type of irrigation system. Crop injury, lack of effectiveness, or illegal pesticide residues in the crop can result from non-uniform distribution of treated water. If you have questions about calibration, you should contact State Extension Service specialists, equipment manufacturers or other experts. A person knowledgeable of the chemigation system and responsible for its operation or under the supervision of the responsible person, shall shut the system down and make necessary adjustments should the need arise. The overhead sprinkler chemigation system must contain a functional check valve, vacuum relief valve, and low pressure drain appropriately located on the irrigation pipeline to prevent water source contamination from back flow. The pesticide injection pipeline must contain a functional, automatic, quick- closing check valve to prevent the flow of fluid back toward the injection pump. The pesticide injection pipeline must also contain a functional, normally-closed, solenoid-operated valve located on the intake side of the injection pump and connected to the system interlock to prevent fluid from being withdrawn from the supply tank when the irrigation system is either automatically or manually shut down. The system must contain functional interlocking controls to automatically shut off the pesticide injection pump when the water pump motor stops. The irrigation line or water pump must include a functional pressure switch which will stop the water pump motor when the water pressure decreases to the point where pesticide distribution is adversely affected. Systems must use a metering pump, such as a positive displacement injection pump (e.g., diaphragm pump) effectively designed and constructed for materials that are compatible with pesticides and capable of being fitted with a system interlock. Do not connect an irrigation system (including greenhouse systems) used for pesticide application to a public water system unless the pesticide label-prescribed safety devices for public water systems are in place. Public water system means a system for the provision to the public of piped water for human consumption if such system has at least 15 service connections or regularly serves an average of at least 25 individuals daily at least 60 days out of the year. Chemigation systems connected to public water 5 systems must contain a functional, reduced-pressure zone, back flow preventer (RPZ) or the functional equivalent in the water supply line upstream from the point of pesticide introduction. As an option to the RPZ, the water from the public water system should be discharged into a reservoir tank prior to pesticide introduction. There shall be a complete physical break (air gap) between the flow outlet end of the fill pipe and the top or overflow rim of the reservoir tank of at least twice the inside diameter of the fill pipe. The pesticide injection pipeline must contain a functional, automatic, quick-closing check valve to prevent the flow of fluid back toward the injection. The pesticide injection pipeline must contain a functional, normally closed, solenoid-operated valve located on the intake side of the injection pump and connected to the system interlock to prevent fluid from being withdrawn from the supply tank when the irrigation system is either automatically or manually shut down. The system must contain functional interlocking controls to automatically shut off the pesticide injection pump when the water pump motor stops or, or in cases where there is no water pump, when the water pressure decreases to the point where pesticide distribution is adversely affected. Systems must use a metering pump, such as a positive displacement injection pump (e.g., diaphragm pump) effectively designed and constructed of materials that are compatible with pesticides and capable of being fitted with a system interlock. Do not apply when wind speed favors drift beyond the area intended for treatment. Application Instructions Follow instructions for system requirements in the Direction for Chemigation section above. This product is only to be applied through systems with anti-siphon valves, check valves, and interlocking controls between the metering device and the water pump to guarantee synchronized shut-off. Such systems are designed and intended to prevent water source contamination or overflow of the mix tank. Be sure to maintain constant agitation in the solution tank before and during the application to assure an even suspension. Better accuracy in calibration and distribution is achieved by injecting a greater volume of a more dilute suspension per unit time. Efficacy may be reduced if this product is applied using more than the specified volume of irrigation water per acre. Do not apply when wind speed favors drift beyond the area intended for treatment. Do not apply when the irrigation system has leaky fittings or connections, when spray nozzles cannot provide even distribution, or when irrigation lines used in applying the product have to be dismantled and drained instead of flushed. In a center pivot system, prevent spray application at the pivot unit by blocking the adjacent nozzle set. Due to their non-uniform distribution, end guns should not be used when chemigating. Improper insect control may result where sprinkler distribution patterns are not sufficiently overlapping. Upon completion of the treatment, continue to run irrigation water until all the remaining pesticide has been cleared through the lines. This product may be applied in combination with liquid fertilizers which are chemically neutral. Avoid applying this product in combination with highly alkaline fertilizers (e.g., aqueous ammonia) as this can cause this product to degrade resulting in decreased efficacy. Spray Preparation Prior to application, flush the injector system and chemical tank with clean water until thoroughly cleaned including removal of scale, pesticide residues, and other foreign matter. Use a mix tank to prepare a solution of this product. Fill the tank with ½ or ¾ the total amount of water to be used. Start agitation and slowly add the required amount of this product followed by the remaining volume of water. Sprinkler Irrigation Follow instructions for system requirements in the Direction for Chemigation section above. Set sprinkler systems such that maximum water delivery is 0.2 inch per acre. Higher volumes of water may reduce product performance. Begin sprinkler and then evenly inject the solution into the irrigation water line to distribute the preferred rate per acre. To obtain satisfactory mixing, inject this product using a positive displacement pump into the main line before a right angle turn. Optimal insecticidal activity is achieved only when this product is retained on foliage. Do not apply when wind speed favors drift beyond the area intended for treatment. Improper insect control may result where sprinkler distribution patterns are not sufficiently overlapping. 6 DIRECTIONS FOR AERIAL OR GROUND SPRAY APPLICATION APPLICATION TIMING Begin application when treatment thresholds for insect populations are reached. Additional information about recognized economic threshold levels may be obtained from the Cooperative Extension Service, professional consultants, or other qualified authorities. INFORMATION This product is a 70% wettable powder intended to control sucking and chewing insects for the listed crops on this label. Acetamiprid, the active ingredient in this product, is a neonicotinoid insecticide which acts through contact and ingestion to control target insects. This product rapidly absorbs into the plant tissue and immediately moves via systemic translaminar activity, providing protection to the entire leaf. However, for optimal control, thorough spray coverage is essential. After this product’s spray solution has dried, it remains effective following rain or irrigation (rainfast). MIXING INSTRUCTIONS Mixing and Application Instructions for Anarchy 70 WP Insecticide This product readily dissolves in water to form a spray mixture, to be applied via ground or air. 1. Prepare only the amount of spray mixture needed for that day’s application. 2. Fill the tank ¼ - ½ full with the total amount of water to be used. 3. Start agitation in the tank and add the required amount of this product. Shake the jug to fluff the product prior to measuring. Refrain from tamping down the product when using the measuring cone because the cone is calibrated to the fluffed product. 4. Direct a stream of water onto any floating product as the tank is being filled to assist in mixing. 5. Mix in tank for 2 minutes or until a thorough mixture is achieved prior to applying. 6. Be sure to maintain constant agitation in the solution tank before and during the application to assure an even suspension. Agitate the mixture before use for 10 minutes if the solution sits stationary for an extended period of time. 7. Equip the spray system with a 50-mesh inline filter. This will protect typically-used nozzles. Spray nozzles may also be equipped with nozzle filters (50-mesh) or slotted nozzle filters (25- to 50-mesh equivalent). 8. This product is unstable in water with a low pH (below 4) or high pH (above 9). Buffer water to attain an optimal pH range, if necessary. COMPATIBILITY/TANK MIXING It is the pesticide user’s responsibility to ensure that all products in a tank mix are registered for the intended use. Users must follow the most restrictive directions and precautionary language of the products of the mixture (for example, first aid from one product, spray drift management from another). This product is compatible with a variety of common spray products, when diluted with equal parts water. However, all potential compatibilities based on local considerations are unknown. To ensure the compatibility of this product with other spray products, conduct a jar test prior to tank mixing. Conduct a jar test with equal parts water and this product and mix thoroughly with added spray product or other pesticide. USE SPRAY MIXTURES DIRECTLY AFTER MIXING WITH SUFFICIENT AGITATION. MIXTURES THAT CURDLE, GREASE, OR PRECIPITATE ARE NOT TO BE USED. Special Instructions for Tank Mixing Anarchy 70 WP Insecticide When tank mixing this product with other products, add them in the following sequence: (1) Water soluble packets (2) Wettable powders (e.g., Anarchy 70 WP Insecticide) (3) Water dispersible granules (4) Flowing liquids (5) Emulsifiable concentrates (6) Adjuvants and/or oils (do not use stickers) 7 Following the addition of each product above, be sure to let full dispersion occur before adding the next product in the sequence. Boron containing products will negatively affect the film solubility of water soluble packets. Therefore, if boron products are to be added to the spray tank mix add the soluble packets first and wait until they are dissolved before adding any boron products. APPLICATION INSTRUCTIONS ROW CROPS Unless otherwise specified in the crop specific directions, apply this product by air at a minimum finished spray volume of 5 gallons per acre or by ground at a minimum finished spray volume of 15 gallons per acre. It is important that equipment be calibrated and adjusted so as to create uniform and thorough spray coverage of the crop. Use nozzle and pressure combinations that distribute MEDIUM spray droplets (see nozzle manufacturer’s catalogs and ASAE Standard S-572) when applying this product by air. To increase plant uptake, spray coverage, and enhance pest control, use with a spray adjuvant, especially in listed vegetable crops (except legumes) and cotton (when controlling whiteflies). Recommended spray adjuvants include high quality non-ionic surfactants, methylated seed oils, or silicone surfactants. Not all adjuvants are safe for the target crop and must be chosen carefully to avoid adverse effects such as burn to foliage or fruit or spotting. See crop specific directions for adjuvant addition recommendations and refer to adjuvant directions for use. Additional information may be obtained from your local Crop Advisor, Extension Service representative, or a representative from Loveland Products, Inc. For dense foliage or heavy infestations, use the higher listed rates. Do not add a sticker in the spray mixture. Specific residual control length depends on many factors including level of insect infestation, dosage rate, plant growth, and environmental factors. If applying through foliar banded application, the amount of product per acre is determined by band width divided by row width then multiplied by the appropriate broadcast rate. When spraying is completed, rinse sprayer with clean water and dispose of the rinsate by applying to an area that has already been treated or dispose of according to the STORAGE AND DISPOSAL section. ORCHARD CROPS For optimal pest control, it is important that equipment be calibrated and adjusted so as to create uniform and thorough crop coverage. To achieve thorough coverage throughout the tree or vine canopy, it is important to choose an appropriate finished spray volume for the size of the tree or vine. See crop specific directions for particular pests. Use nozzle and pressure combinations that distribute MEDIUM spray droplets (see nozzle manufacturer’s catalogs and ASAE Standard S-572) when applying this product by air. Coverage by aerial applications may not be as thorough as ground applications. To increase plant uptake, spray coverage, and enhance pest control, use this product with a spray adjuvant, especially in pome fruit (when controlling codling moth, oriental fruit moth, and San Jose scale). Recommended spray adjuvants include high quality non-ionic surfactants, methylated seed oils, or horticultural oils. Not all adjuvants are safe for the target crop and must be chosen carefully to avoid adverse effects such as burn to foliage or fruit or spotting. See crop specific directions for adjuvant addition recommendations and refer to adjuvant directions for use. Do not add a sticker in the spray mixture. Additional information may be obtained from your local Crop Advisor, Extension Service representative, or a representative from Loveland Products, Inc. For dense foliage or heavy infestations, use the higher listed rates. Specific residual control length depends on many factors including level of insect infestation, dosage rate, plant growth, and environmental factors. When spraying is completed, rinse sprayer with clean water and dispose of the rinsate by applying to an area that has already been treated or dispose of according to the STORAGE AND DISPOSAL section. INTEGRATED PEST MANAGEMENT (IPM) USE OF THIS PRODUCT This product can offer substantial benefits to producers using IPM programs. This product has adulticidal, larvicidal, and ovicidal activity against many pests. This product can be effectively utilized in IPM programs to control important pests combined with maintenance of beneficial insects and spiders. 8

Description: