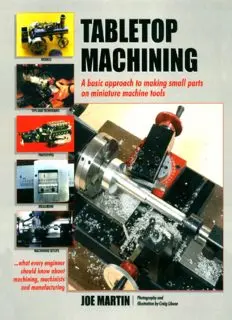

Tabletop Machining: A Basic Approach to Making Small Parts on Miniature Machine Tools PDF

Preview Tabletop Machining: A Basic Approach to Making Small Parts on Miniature Machine Tools

I aLETOP CHINING , A basic approach to making small parts on miniature machine tools .••w hat every engineer shauld know about machining, machinists and manufacturing I'trotogrup/ry ami illustration by Cruig Ubuse A special note to engineers reading this book_ Machining for engineen and to put a perfect .0001" radius on the inside comer of engineering for machinists a pocket cut in tool steel. Hopefully after reading At first glance the subtitle on the cover of this book this book you will not ask a toolmaker to do it, but could be a bit deceiving. What does tabletop if you do, you'll at least know it is going to cost a machining have do with engineering you may ask? great deal of money to try. Working with metal is Compare it to a book that has been written about far more difficult than one would imagine. A false the ocean. The seas could he described from the impression is gained by looking at the beautiful yet perspective of a young man who has just sailed inexpensive machined parts that we deal with daily. around the world in a twenty-five foot sailboat or They have been produced in very large quantities, by a merchant seaman who has spent his career and that five-dollar part you may consider a "rip aboard a giant ocean liner. Each would have an off' could easily cost five hundred dollars if you entirely different view of what the ocean was all had to manufacture just one. New engineers will about. In a stenn, the chap in the small boat would often think a toolmaker is a failure when the write ahout surviving broken masts and seemingly simple part they design ends up costing mountainous seas while the merchant seaman might a thousand dollars to make. Most engineers will write about seasick passengers. I believe you would eventually have to deal with the craftsman who tum learn more ahout the ocean from the young man in their ideas into reality, and in reading this book I the small boat, because in a sense he was more would hope you come away with a new perspective involved in his subject. He was not just on it, he of what is really involved in producing a machined was in it. part or a product. An alternate subtitle for the book might have been "Things they should have taught Navigating the seas of machining you in engineering school but didn't". This book The ocean in this case is the world of machining. might be considered your textbook for a course The craftsman using tabletop machine tools is like called "Reality WI". the sailor in a small boat, while the professional machinist with his big CNC shop tools is like the Seeing produdion from the point of view of both world-traveling seaman. The process of producing the engineer and machinist complex, accurate parts cannot be described by My perspective on machining could be considered looking in the window of a quarter million dollar unique because, in order to survive, I have had to CNC machine. It would be like a merchant seaman deal with every aspect of product design from working in the engine room trying to describe a engineering to prototyping to tooling to stonn in the Atlantic Ocean by telling you how much manufacturing to sales. In this book I have tried to extra fuel the ship used. The professional's view of pass along the logic I used to solve the associated the subject may be so cluttered with details that it is problems. Understanding how a craftsman thinks difficult to sort the things you really need to know and works is an essential part of getting projects to sail in rough seas or make good parts. I t is the done. Unless you are willing to build your designs craftsman working with small tools, turning the yourself, you are going to have to learn how to deal cranks by hand, who will have the most to tell you with the craftsman who will actually build them. about the real world of working with metal. The more you know about their methods. personalities and unique problems, the better your looking at engineering from chances are for success. Smooth sailing. the craftsman's perspedive With the aid of computers, parts can easily be drawn - Joe Martin that can't be built. CAD prvgrams allow a designer About the Author Joe Martin worked in you some of his hard-won the construction trades knowledge about machin after graduating from {tiERLi ing. His down-to-earth high school, but his real style is not highly love was always building polished. In fact, if you and flying radio con could say that life has put trolled model airplanes. ~RODU( a finish on him, it would When he decided to turn probably be described as his hobby into a business "" ground or honed ... very and start his own accurate but not slick. I company making components for the radio control think his heartfelt love of good tools and miniature industry, he had to learn about machining and machining will be apparent to all who read this book. toolmaking on his own. He simply couldn '{ afford Working with him these past 25 years is certainly to hire anyone else to set up the tools and make the an experience I would not have wanted to miss. molds. He has designed and taken to market - Craig Libuse numerous products and owned several companies over the years. He began his association with Sherline Products as an importer of Australian-built lathes in the early 1970's. Since then, Joe's company has grown to become the sole manufacturer and worldwide distributor of Sherline machine tools. Joe was one of the founders of the sport ofFonnula One model aircraft competition as well as one of its early champions. His competitive nature seems to find its way into whatever form of fun he pursues. He has been a winner in sports from model airplane competition to ocean sailboat racing and, most recently, automobile racing. Never one to be a spectator in life, he has tried and Joe at speed in a 1974 vintage indyCar at Phoenix mastered many skills. In this book, he passes on to international Raceway. " DEDICATION Carl Hammolis- /936-J997 Carl Hammons, my friend and business partner along without it. It may seem contrary to smart for thirty years. died September 11, 1997 as I business practice, but that's the way we did it. I have was writing this book. We shared thousands of no regrets, for we were always the happiest when lunches and coffee breaks over the years we worked we were confronted with a new set of technical together, and much of the knowledge I have passed problems. Therefore. I dedicate this book to Carl on in this book came from Carl. Carl and I shared Hammons: my business partner, my friend. the rare distinction of having been partners not just once, but twice. We both played different roles in putting together the product line, and without him I should also credit the English teachers in the it just isn't going to be as much fun. Cranston, Rhode Island school system for forcing a When we joined forces for the second time. we had not-so-willing student enrolled in the "boys general an agreement that eliminated any need to financially class" to learn enough about our language to dare to justify the purchase of a new piece of equipment. take on the task of expressing difficult concepts in We would buy machines that interested us and find simple words. I graduated in 1953. You, the reader, a job for them later. The laser engraver was a will be the ultimate judge of their (and my) success perfect example of this, but now we couldn't get in this undertaking. - Joe Martin The photo COII/positioll ahol'e ix ajoillt effort. The photo a/Carl II'OS taken by his wife Barbara. The photo o/Swall Lake. MOil/alia. a /m'odle spot oj Carl's, was takeu byfrieud WaYl1e Arll/s/rOllg. The two images were composed ill PIIO/OShopl by artist £Ioille lolli/IS Table of Contents Safety Rules ...... ..... ... ...... .. ........ I I. Holding parts for milling. . . . . . . . . . . . . 183 Foreword. . ... ..... .. ........ 3 2. Mill operating instructions.. . . ........ . 191 Introduction ............................. 5 3. Squaring up a block ...... ........ .. .... 205 A gallery of machining project photos ..... ... ]0 4. The rotary table and indexing attachment ..... 209 5. Gears and Geartrains ................... 219 SECTION I-GENERAl MACHINING Craftsman Profile-Scotty Hewitt ........... 24 6. Accessories for milling • Horizontal milling conversion .... ...... 235 I. Getting information on machining. . . . . . 27 • Rotary column attachmcnt . . . . . . .. 237 2. Do you need a lathe. a mill or bOlh? ........ 29 SECTION 4-OTHER MACHINING TOPICS 3. Materials for metalworking .............. 39 Craftsman Profiles-Dan Lutz and Paul White . 242 4. Processes for metalworking 4. I- Heat treating ............ ..• ...... 45 I. Setting up a small workshop .... .... .... . 247 4.2-Metal finishes ........... . ........ 46 2. Lathe and mill alignment and adjustments .. 251 4.3-Castings. . . ... .... ..... .... 49 3. Enginering drawings ..... .. ............ 259 4.4-----0ther ways 10 form metal .. .. .. . .. .. 51 4. Frequently asked questions . . . . .. . . . .. . . 265 4.5- Joining metal- Soldering 5. Making a business out of a hobby .. .Joe Martin's and welding . . . . . . . .. . ... . .. . 52 and Sherline's story ................... 273 5. Using hand tools and abrasives .......... .. 57 6. Using CNC in a home shop ... ........... 309 6. Cutting tools for metalworking SECTION S-PROJECTS AND RESOURCES 6. I- General notes on cutting IDols . . 63 6.2- Cutting tools for both Craftsman Profile-Bob Breslauer ........... 316 the lathe and mill ................... 65 Machinist's tips .......................... 318 6.3-Lathe cutting tools ................. 72 I. Plans and projects you can build ........... 319 6.4-Culter,S for milling ...... ....... .... 81 1. Miniature Tap Handle ... a beginning 7. Measuring and measurement tools . . . 85 project you can use in your shop ........... 321 8. Coolants and CUlling oils ................ 99 2. Mill vise "sofe jaws. . . . . . . . . . . . . . . . 325 3. Laying out a circular hole pattern 9. General machining terms . . .. . 101 fordrilling, a handy skill to learn. . .. . 327 10. Machine tool lubrication and maintenancc . 107 4. "Millie" ... a small oscillating steam SECTION 2-LATHE OPERATIONS engine by Ed Warren, a simple project Craftsman Profile-Jerry Kieffer ..... .. .. .. . 112 from the pages of Modeltec magazine) ..... . 329 Jerry Kieffer's Flying Pendulum Clock .. ... 114 5. Ordering plans for the "Little Angel" hit 'n miss engine ... an advanced I. Lathe work holding ... .. . .. ... .. .. . .. . . 115 machining project by Bob Shores .......... 333 2. Lathe operating instnlclions . . . .......... 121 2. Contests and awards for tabletop machinists .. 335 3. Tailslock lools and operations . . . . ....... 141 3. Exploded views and part number listing 4. Riser blocks .. . . . . . . . . . . . ............ 145 • Model 4000 and 4400 Lathes .. ......... 340 5. Supporting long or thin work . .... ... . . .. 149 • Model 5000 and 5400 Milling machines ... 341 6. Gelling started in thread cutting. . . . .. 157 • Model 2000 8-Direction Mill Column ..... 342 7. Knurled finishes. . . . . . . ... .. ........ 167 • Part number listing ... .... ......... ... 343 8. Watchmaking and clockmaking tools . ... . 171 4. A simple RPM gage for your latheor mill ... . 345 9. Milling operations on a lathe . . . ... . . .... 177 Harold Clisby and the first Sherline lathe .... . 346 S. Index ............. .... ...... . . . 347 SECTION 3-MIll1NG OPERATIONS Craftsman Profile- Augie Hiscano ......... . 180 • Conversion faclors .. .... .... .. ........ 350 Modeling Miniature Machine Tools 101'TW<I1'II010\, ..... _ YOU will probably not be surprised to find that people who are interested in miniature machine tools onen find it fun to make miniature models of full-size tools. This page shows beautiful examples of a lathe and a mill from two expert craftsmen. Barry Jordan built a 2/1 diameter rotary table and then needed a mac/line to Lise it on. The result was this //5 scale Bridgeporl® mill. The project was started in 1997 and completed just in time for The pans are all machined/rom aluminum alld billet Bridgeport's 60th anniversary in 1998. What started cast iron. No castings were used. The polished as a model filmed into a real machine in miniature, pulley cover is made from Dural. More of Barry capable of actually "cutting small parts in mild steel. Jordan s miniature tools can be seen on page 246. This small but fully functional //6 scale Hardinge lathe was modeled by Wilhelm Huxhold of Ontario, Canada. A lifelong machinist, he shows his love for machine tools by modeling them in miniature. Unlike Barry Jordan s Bridgeport, this project took many years to complete. More of Mr. Huxholds work can be seen on pages 22 and 2 I 7. A profile of his career is presented on page 330. INING ... A basic approach to making small parts on miniature machine tools JOE MARTIN Design, typesetting, illustration and photography by Craig Libuse Machining is not a Mpaint-b,-numbers" process If you are looking for a book that will give you complete, step-by-step instructions on how to build your particular machining project. this is nOI it. In fact. that book probably does not exist. Whallhis book will give you is all the basic knowledge you need to start machining metal. Your imagination plus the information in this book will allow you to make just about anything. The many photos showing what others have done are here to spark your imagination. None of the projects shown in-the photos in this book came with detailed instructions. Most came with none at all. They are, for the most part. not beginner projects. I'd suggest you start with a relatively simple project and apply what you learn from this book. As your skill and experience increase, you'll be ready to tackle anything you see here. Read the parts about tools and materials. Read the parts about speeds and feed rates. Study the photos of setups carefully. Everything you need is right there. but you have to use some brainpower to apply it to your projects. The level of satisfaction you achieve will be directly related to the amount of effort you are willing to put forth. The book is now in its fourth printing, and some have commented that it doesn't contain enough project plans. I have avoided adding a lot of "how to" plans in order to concentrate on the general skills. craftsmanship and techniques needed to create a good part. These will never be found in a set of plans. For those looking to lake whallhey've learned here and apply it to a specific project. there are many sources of kits and plans on Sherline's web site at www.sherline.com.Severalmagazineslike s The Home Shop Machinist and Machinist Workshop offer new plans in every issue. Thanks to _ who helped Joe Martin and Craig Libuse would like to thank all of those who took the time to read this book word for word and sent in suggestions for corrections in the previous printings. Our thanks go to Marc Cimolino. Jim Clark, Glenn Ferguson Jr. . Mort Goldberg. Alan Koski and especially Huntly Millar for their extremely diligent, voluntary efforts. Among other things. this book addresses the issue of quality and the quest for perfection. so we have made every atlempt to eliminate any typographical errors. We welcome your input in a continuing effort to improve the quality of this book. Though rarely achieved, perfection is a goal always worth pursuing. 02004 by Joe Man;n Firsl prinling~l99g. second prinling~I999. l~ird prinlin8~2001. fourth prinlin8~2004 All righlS resclV<'d. PrinlCd in China by Win<:o (H.K.) Co. LId. 'The aUlhor takes "" responsibilily for lhe usc or applie'li"" of any of lhe malerials or mc:lhods described in lhis book. All mini.1Un: projeclS SOOW" w<:re eilher made or could be made using lah)tlop mach;!\(' lOO)~ similar 10 or identical to those described in lhis book. To order additional copies of this book call: Toll free in lhe USA~800) S41.G73S· Imem31iooal-I·760-727·S8S7 or ",rile 10: Joe Martin. 3235 E.eculi,·c Ridgc. Vista. California 92081 ISBN 0-9665433-0-0 Safety rules for power tools A poHernmaker's interview for employment 4. REMOVE ADJUSTING Km AND WRENCHES-Form a One of the best patternmakers I ever knew habit of checking 10 see that keys and adjusting apprenticed in the trade for many years with his wrenches are removed from the tool before turning father. When he went to work for U.S. Steel in their on your machine. pattern shop, the foreman who was interviewing him 5. KEEP WORK AREA CLEAN-Cluttered areas and for the job asked him to hold out his hands. When benches invite accidents. the foreman could see that the applicant still had all 6. AVOID DANGEROUS ENVIRONMENT-Do not usc ten fingers, he was hired. The foreman could see power tools in damp or wet locations. Keep your from his work that the patternmaker was a good work area well illuminated. craftsman, but he figured that ifhe had been working 7. KEEP CHILDREN AWAY-All visitors should be kept in the trade that long and still had all his fingers he a safe distance from the work area. must be a good, safe worker too, and that was just as important. 8. MAKE WORKSHOP KID PROOF-with padlocks. master switches or by removing starter keys. Spinning tools that are powerful enough and sharp enough to remove metal can also remove just about 9. DO NOT FORCE TOOL-Do not force a 1001 or anything else that gets in their way. Though less attachment to do ajob for which il was not designed. Use the proper tool for the job. dangerous than their larger full size shop counterparts, small power tools can still cause 10. WEAR PROPER APPAREl-Avoid loose clothing, serious injury to those who don't show them the neckties, gloves or jewelry that could become caught proper respect. Even hand tools used improperly can in moving parts. Wear protective head gear 10 keep cause injury. Talking about safety is not nearly as long hair styles away from moving parts. fun as talking about the beautiful miniature 11. USE SAFETY GLASSES-Also usc a face or dust mask machining projects in this book, but working safely if cutting operation is dusty. is part of the skill of a good craftsman. 12.SECUREWORK-Use clamps or a vise to hold work Working safely is simply a series of habits that you when practicable. It is safer than using your hand develop. Once they become habits, it takes no longer and frees both hands to operate the tool. and is no less enjoyable to work that way than to 13. DO NOT OVERREACH-Keep your proper footing work with unsafe habits. Injuries definitely take the and balance at all times. fun out of working with tools, and fun is what 14. MAINTAIN TOOLS IN TOP CONDITION-Keep tools miniature machining is all about. Please read these sharp and clean for best and safest performance. rules and apply them until they become habits so Follow instructions for lubrication and changing that you can enjoy your hobby to the fullest. accessories. IS. DISCONNECT TOOLS-Unplug the tool before 1. KNOW YOUR POWER TOOL-Read the owner's servicing and when changing accessories such as manual carefully. Learn the tool's application and blades, bits or cutters. limitations as well as the specific potential hazards 16. AVOID ACCIDENTAL STARTING-Make sure the peculiar to this tool. switch is "OFF" before plugging in power cord. 2. GROUND ALL TOOlS-If a tool is equipped with a 17. USE RECOMMENDED ACCESSORIES-Consult the three-prong plug, it should be plugged into a three owner's manual. Use of improper accessories may hole receptacle.! fan adapter is used to accommodate be hazardous. a two-prong receptacle, the adapter wire must be 18. TURN SPINDLE BY HAND BEFORE SWITCHING ON attached to a KNOWN GROUND. Never remove MOTOR-This ensures that the workpiece or chuck the third prong. (See drawing on next page.) jaws will not hit the lathe bcd, saddle or crosslide, 3. KEEP GUARDS IN PLACE-and in working order. and also ensures that they clear the cutting tool. 19. CHECK THAT ALL HOLDING, LOCKING AND DRIVING _.,.,,::::;, GROUNDING rIPE 3·PRONG PlUG DEVICES ARE TIGHTENED-At the same time, be careful ~@).. ~ PROPERLY not to overtighten these adjustments. They should GROUNDED -..-.. ',' be just tight enough to do the job. Overtightening TYPf OUTLET I a USE PROPERLY GROUNDED may damage threads or warp parts, thereby reducing @) RECEPTA.ClE AS SHOWN accuracy and effectiveness. 20. WHEN WORKING THROUGH THE SPINDLE, DO NOT LET LONG, THIN STOCK PROTRUDE FROM THE BACK END OF THE SPINDLE SHAFT-The end of unsupported stock turned at high RPM can suddenly bend and whip around. Proper grounding ofe lectrical connections. 21. I t is not recommended that the lathe he used for grinding. The fine dust that results from the source, the machine will operate on any current from grinding operation is extremely hard on bearings and 100 to 240 volts AC and 50 or 60 Hz. without a other moving parts of your tool. For the same transformer·. This should include just about any reason, ifthe lathe or any other precision tool is kept country in the world. Prior to 1994, an AC/DC near an operating grinder, it should be kept covered motor was used. Use the ACIDC motor ONLY with when not in use. the power source for which it was intended. It will 22. WEAR YOUR SAFETY GlASSES-Foresight is better not automatically adapt to any other current and than NO SIGHT! The operation of any power tool using it with an improper power source will bum can result in foreign objects being thrown into the out the motor or speed control. eyes, which can result in severe eye damage. Older ACIDC motOR available from Grainge, Always wear safety glasses or eye shields before Sherline's supply of older ACIDC motors is slowly commencing power tool operation. We recommend being depleted. A very large run must be custom a Wide Vision Safety Mask for use over spectacles ordered to get more, and this is not economically or standard safety glasses. feasible. However, the Grainger catalog stocks a 115 horsepower motor identical to the one used on early Sherline tools. The catalog number is 2M139. ELECTRICAL CONNECTIONS They have locations in every state and can be found The power cord used is equipped with a 3-prong in the Yellow Pages under "Electric Motors". Their grounding plug which should be connected only to web address is www.grainger.com. Your other a properly grounded receptacle for your safety. option would be to upgrade your motor and speed Should an electrical failure occur in the motor, the control to the newer, more powerful DC version. grounded plug and receptacle will protect the user from electrical shock. If a properly grounded receptacle is not available, use a grounding adapter "The first DC units built in early 1994 did not include the to adapt the 3-prong plug to a properly grounded circuits to adapt to other currents. The capability to include that feature was not available to Sherline at that time. As soon receptacle by attaching the grounding lead from the as it was, it was included. If you think you may have an early adapter to the receptacle cover screw. DC model, remove the plastic speed control housing and look NOTE: Electrical circuits designed into the speed for a label on the aluminum speed control frame. If it has a small metallic label on top of the frame that lists input voltage control of the Sherline lathe or mill read incoming as 120VAC, DO NOT A lTEMPT TO CONVERT THIS current and automatically adapt to supply the correct UNIT TO OTHER CURRENTS. Models that can be used with 90 volts DC to the motor. As long as you have a any current have a paper label on the end of the speed control properly wired, grounded connector cord for your frame which lists the model number as KBLC-240DS. "Common sense is instinct, and enough ofi t is genius." - Josh Billings (1818·1885) 2 FOREWORD What is "tabletop machining"? craftsmen build beautiful projects for enjoyment, not Tabletop machining is about operating miniature wages. These are special people who may suddenly machine tools. These are machines that can be picked have an urge to accurately build that model they up and set on a small bench or, if need be, a kitchen have dreamed of for years. The machinists who are table, and used to build precise metal parts. They successful will realize there is a learning curve are inexpensive compared to their full-size shop involved in accomplishing this. This book is about equivalents, but are just as versatile and accurate as shortening that learning curve and giving you a new long as the size of the part is appropriate for the sense of what craftsmanship is all about. machine. The "Unimat" was the first miniature lathe Nat just the "how" but also the "why" mass produced and well known. Thousands of I The tables and charts can be found in Mochil/ery S Unimats were sold, and today many are still in usc. Handbook, and I don't plan to duplicate them in this Il had a wide variety of accessories manufactured book. Library shelves are full of books of this for it and a price that was affordable. A number of nature. The infonnation in this book won't be found other miniature machine tools have been in charts and graphs. I'm going to attempt to give manufactured since the Unimat, and the company I you the infonnation to actually start making "parts". own, Sherline Products Inc .• has become lOday's Instructions that tell you "how" to do ajob too often leader for this class of machine. I believe the fact I skip the most basic information, and that is "why" am both a hobbyist and toolmaker gave me more you would want to do a job this way or that way. I insight into what our customers needed when it believe the customers who purchase miniature comes to both accessories and instructions. machines are intelligent enough to find the specific infonnation they need al a library. These customers just don't happen to know much about machining. However, I also believe this book contains enough general rules lO get a job done. Get started on a project as soon as you have your tools set up and working. Read a little, machine a little. Never cut metal without a plan that includes dimensions. "Making chips" without a plan can develop terrible work habits. This trade has few choices when it comes to parts fitting together. To work in unison they must be accurate, and your first task should be to make parts "to size". How to read this book The original Unimat lathe was the first miniature A book like this doesn't need 10 be read from front machine tool to achieve international popularity. It to back like a novel. You will probably skip around came in a professional looking wood box and offered reading first the sections that interest you the mosl. a versatile design and mallY accessories at a Therefore, this book may seem at times to be reasonable price. Its two· rail bed design made it redundant. I have attempted to make each chapter too flexible for jobs requiring a high degree of relatively complete in and of itself. and some rules accuracy, bm it introduced many people to the fun apply to more than one machining operation. Some of machining in miniature. of the more important ones may be repeated Beating the system wherever they apply. To keep you interested and For me there has always been something special make the book more fun, we have included many about projects that have been built on these small pictures of actual projects and the people who made machines. The machinist who works with miniature them. The examples of what has actually been done machine tools will have beaten the system by not using tabletop machine 10015 speak more eloquently spending thousands of dollars on tools. These about their capabilities than anything I could say. 3