PIAB Vacuum Academy Conveyors C Index Conveyors IC Accessories PDF

Preview PIAB Vacuum Academy Conveyors C Index Conveyors IC Accessories

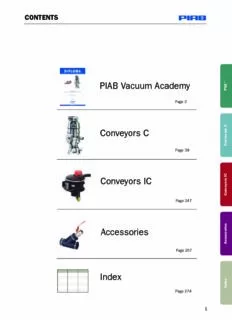

CONTENTS PIAB Vacuum Academy M AT V P Page 3 C Conveyors C s r o y e v n o C Page 39 C Conveyors IC s I r o y e v n o C Page 247 s e Accessories ri o s s e c c A Page 257 Index x e d n I Page 274 1 PVA™ PIAB Vacuum Academy PIAB VACUUM ACADEMY EMPHASIZES THE BASICS In industry today there is an accelerating trend toward ever more customized solutions that can be made avail- able at short notice. Product development times and production runs are both becoming shorter. Changes are becoming more sudden and harder to predict. Competence and willingness to change are being challenged by a never-ending parade of new situations. Train- ing that sharpens skills and broadens perspectives enables your personnel – and your company – to handle more sophisticated assignments while accepting highly qualified responsibilities. This makes it easier for you ™ to develop new functions and work pro-cedures while advancing into new markets. A V P PRINCIPLES OF VACUUM CONVEYING .........................................................................................................................4 A TYPICAL VACUUM CONVEYING SYSTEM .........................................................................................................................5 MATERIAL HANDLING .........................................................................................................................6 PNEUMATIC CONVEYING SYSTEMS .......................................................................................................................10 HANDLING DRY PRODUCTS HYGIENICALLY .......................................................................................................................14 COMPONENTS OF A VACUUM CONVEYING SYSTEM .......................................................................................................................15 CONVEYING PIPELINE .......................................................................................................................16 SYSTEM DESIGN .......................................................................................................................17 SYSTEM EXAMPLES .......................................................................................................................21 VACUUM PUMPS .......................................................................................................................26 COMPRESSOR ENERGY CONSUMPTION .......................................................................................................................28 TABLES .......................................................................................................................29 THREAD SYSTEMS .......................................................................................................................33 INTERNATIONAL STANDARDS .......................................................................................................................34 ENCLOSURE CLASSIFICATIONS FOR ELECTRIC EQUIPMENT .......................................................................................................................36 APPLICATION FORM FOR VACUUM CONVEYORS .......................................................................................................................37 The PIAB Vacuum Academy trains your company’s employees to make sounder pre-purchasing de-cisions, find new fields of applica-tion, develop production process-es and make your business more profitable. Training courses are held wher-ever PIAB is represented. More-over, they can be held on your company’s premises and be adapted to meet special needs whenever you desire. 3 Specifications subject to change without notice. PVA™ PIAB VACUUM ACADEMY PRINCIPLES OF VACUUM CONVEYING PATM P- In the field of vacuum conveying technology we into the pipeline. speak of vacuum conveyors being used for “sucking” All vacuum conveyors work according to the same material. What actually happens is that the air is main principle, as illustrated below. The material is evacuated from the suction pipe and the pressure of conveyed from a suction point through a pipeline to the atmosphere pushes the material into the suction a container, where the air and the material are sep- pipeline. It is the atmospheric pressure that indirect- arated. The filter cleans the air before it passes ly performs the work. The stream of air that is formed through the vacuum source. A control unit regulates upon pressure equalization pulls the solid particles the operating sequence. Block Sketch, Vacuum Conveying Control Equipment r e Vacuum Pump ter ain Pipeline Suction Fil nt Point o C 4 PVA™ PIAB VACUUM ACADEMY A TYPICAL VACUUM CONVEYING SYSTEM A G A. PIAB vacuum pump B. Bottom valve F C. Inlet container ™ D. Pipeline (hose or pipe system) H A V E. Feed station P F. Filter C G. Air shock tanks B H. Control system D E 1. Vacuum is generated by a compressed air-driven 5. During the suction period, the air shock tanks (G) PIAB vacuum pump (A). The pump can easily be are filled with compressed air. automatically controlled. Since it has few moving 6. When the material container is full, the vacuum parts, the pump is virtually maintenance-free. pump is stopped. The bottom valve opens and the 2. The bottom valve (B) is closed, and vacuum is material in the container is discharged. At the raised in the container (C) and the conveying pipe- same time, the compressed air in the filter tank is line (D). released and cleans the filter 3. From the feed station (E) the material is drawn 7. When the pump is restarted, the process is re- into the conveying pipeline and then on to the con- peated and a new cycle begins. The suction and tainer. discharge times are normally controlled by pneu- matic or electrical control systems (H). 4. The filter (F) prevents dust and fine particles from being drawn into the pump and escaping into the surroundings. 5 PVA™ PIAB VACUUM ACADEMY MATERIAL HANDLING MATERIAL FLOW range of phase densities may occur. Dense phase means that the material is conveyed in The material flow is determined by the diameter of separate plugs in the conveying pipeline. For most the conveying pipeline, the vacuum flow, conveying materials, the phase density is a factor above ten for distance and not least by the characteristics of the dense phase. Some materials can be conveyed in material. dense phase. The relationship between material flow and vacuum Another conveying phase is “dilute phase”. The flow is usually stated as phase densities and is a di- phase density is usually below ten. Conveying speed mensionless quantity. If the phase density is the in dilute phase is usually >30 ft/s. same as the bulk density, it means that there is no The figure below shows conveying phases with differ- air in the conveying pipeline and that the pipeline is ent phase densities. From very dilute phase (1), over blocked. The converse also applies. If the phase dense phase (6) to blocked pipeline (7). density is equal to zero, there is no material in the conveying pipeline. Between these two limits, a Material flow material lb/h * Phase density = Vacuum flow conveying air lb/h Flow direction 1 5 2 6 3 7 6 PVA™ PIAB VACUUM ACADEMY It is generally the case that in dense phase, because the material moves in the form of plugs, the vacuum Q Material Flow level is usually 30–65%, while in dilute phase it is 10–30%. Q max When sizing a conveying installation, it is important to find the optimum conveying phase for a specific material. A common misapprehension is that the greater the vacuum flow, the higher the material flow. The relation between material flow and vacuum flow may, for example, be as shown in the opposite Q v Q Vacuum Flow ™ figure. The diagram shows that the maximum mate- A V rial flow Qmax is equivalent to the vacuum flow Qv. P When the vacuum flow increases, the material flow will decrease. When sizing a conveying installation, it is important FLUIDITY to find the optimum point of the curve. The only way The fluidity is one of the most important qualities of ascertaining the position of maximum material when the conveying possibilities of a material shall flow for a specific product is to experiment with var- be decided. One way of making a rough assessment ying degrees of aeration and vacuum flow. For this of the fluidity is to determine the material’s angle of purpose many manufacturers have special test repose by pouring out the material from a height and plants. measuring the angle (a). A small angle of repose means good fluidity and a MATERIAL CLASSIFICATION large angle of repose, poor fluidity. The factors that When sizing a conveyor, it is important to determine determine the fluidity of the material are particle the fluidity of the material that is to be conveyed. size, geometric shape, tendency to pick up static To sum up, the following points should be included electricity and degree of moisture sensitivity. Plastic in the material classification: granules generally have good fluidity while corn flour (cid:88) Fluidity/angle of repose has poor fluidity and is also sensitive to moisture. (cid:88) Bulk density Material with poor fluidity can often be fluidized. For fluidization to work, the material must be reasonably (cid:88) Abrasion factor fine so that it is lifted by the fluidizing air. If the ma- (cid:88) Particle terial consists of coarse particles, fluidization will – size not be so effective. – distribution – form – density – hardness (cid:88) Moisture sensitivity (hygroscopicity) (cid:88) Explosion hazard (cid:88) Harmfulness/poisonousness a 7 PVA™ PIAB VACUUM ACADEMY BULK DENSITY MOISTURE SENSITIVITY The term “bulk density” refers to the weight/volume Different materials are more or less hygroscopic. If of a material, in other words, how much one cubic test running is carried out on a particular material, it foot of the material weighs. As one cubic foot of is important that the conditions are kept as similar powder contains both material and air, the bulk den- as possible to those that will apply on installation. A sity will vary considerably depending on how closely moisture-sensitive material may form lumps that a particular material is packed. In other words, the catch in the material intake, stick in the pipeline or same material will have different bulk density values block up the filter. if you weigh a cubic foot of material that has been poured into a beaker and a cubic foot of material that has been shaken and packed. It is therefore im- portant to measure bulk density under conditions that are as similar as possible to the actual convey- ing conditions. PARTICLES Individual particle weight, size, distribution, form and hardness are all parameters that determine a mate- rial’s flow ability and thus its conveying characteris- tics. The weight (density and size) of the individual parti- cles determines the vacuum flow that is required to lift the material into the conveyor pipe and move it forward in the pipeline. The term “particle distribution” refers to how much of various-sized particles, from the smallest to the largest, make up the material’s composition. 8 PVA™ PIAB VACUUM ACADEMY EXPLOSION RISK HARMFULNESS AND TOXICITY In connection with handling of finely ground material, A vacuum conveying system is appropriate for con- there may be a risk of dust explosion. Dust explo- veying harmful materials, as any leakage in the sys- sions can occur when certain types of particles are tem does not allow the conveyed material to leak out mixed with air at a certain ratio and a source of igni- into the surroundings because of the lower pressure tion is present. Rapid expansion and pressure in- within the system. crease are characteristics of dust explosions. The air extracted from the system may need to be fil- Dust explosions that occur during conveying of mate- tered particularly carefully by means of a special fil- rials are commonly caused by sparks from static ter or be piped away to a central filter system. electric discharge. You can read more about this in ™ the statute book of the Swedish Board for Occupa- A V tional Safety and Health AFS 1981:5 concerning P dust explosions. In a vacuum conveyor, the ratio of the air-to-material mixture (phase density) varies and the risk of a dan- gerous mix cannot be eliminated entirely. The risk of ignition can, on the other hand, be minimized by pre- venting electrostatic discharge and thus the genera- tion of sparks. This can be achieved by connecting the various parts of the conveyor system to the same earth point (equipotential connection). Many common materials have a tendency to cause dust explosions. Examples of such materials are giv- en below. A complete list may be found in the above- mentioned statute book published by the Board for Occupational Safety and Health. (cid:88) Aluminium (cid:88) Flour (cid:88) Aspirin (cid:88) Grain (cid:88) Carbon (cid:88) Iron (cid:88) Coffee (cid:88) Nylon (cid:88) Cork (cid:88) Sugar (cid:88) Cotton (cid:88) Tea (cid:88) 9 PVA™ PIAB VACUUM ACADEMY PNEUMATIC CONVEYING SYSTEMS GENERAL From a technical point of view, pneumatic conveying Pneumatic conveying depends on access to com- is based on conveying of solid particles mixed with a pressed air or a source of vacuum, a feed device gas, usually air. where air is mixed with the solid particles, a convey- ing pipeline and a receiving device that separates By means of pneumatic conveying, solid particles of the carrier air from the particles. varying sizes can be conveyed between points, for example, from a storage to a processing machine. PNEUMATIC CONVEYING SYSTEMS ARE DIVIDED INTO THREE CATEGORIES: A.Positive-pressure systems, where the material is C.Fluidized beds. The force of gravity is utilized in blown through the conveying pipeline by com- combination with fluidization. pressed air. The fluidizing layer of air lowers the friction and makes the material run like a liquid. B.Negative-pressure systems where the material is “sucked” through the conveying pipeline. B C A 10

Description: