Mont Anl HSW-ARCOS gb PDF

Preview Mont Anl HSW-ARCOS gb

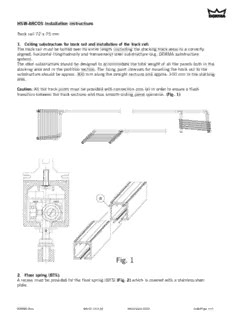

HSW-ARCOS Installation Instructions Track rail 72 x 75 mm 1. Ceiling substructure for track rail and installation of the track rail: The track rail must be bolted over its entire length (including the stacking track area) to a correctly aligned, horizontal (longitudinally and transversely) steel substructure (e.g. DORMA substructure system). The steel substructure should be designed to accommodate the total weight of all the panels both in the stacking area and in the partition section. The fixing point intervals for mounting the track rail to the substructure should be approx. 300 mm along the straight sections and approx. 100 mm in the stacking area. Caution: All the track joints must be provided with connection pins (a) in order to ensure a flush transition between the track sections and thus smooth sliding panel operation. (Fig. 1) a Fig. 1 2. Floor spring (BTS): A recess must be provided for the floor spring (BTS) (Fig. 2) which is covered with a stainless steel plate. DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 1/14 Recess for double action end panel (Fig. 2a) a 63 BTS 75 = 50BTS 80 = 60BTS 84 = 40 BBBTTTSSS 788504 === 555111---555778 BBBTTTSSS 788504 === 233940116 Fig. 2 3. Fitting the door rails to the glass panel: The door rail consists of two sections which are bolted together in and alternate-side pattern and slid over the glass. After aligning the door rails (taking into consideration that the thickness of the end covers is 4.5 mm on both sides), firmly tighten the M8 hex socket screws on both sides so that the rails clamp the glass securely (5 mm Allan key). The tightening torque should be 20 Nm. It is particularly important to clamp the upper door rail correctly due to its bearing function. If the system is likely to be subjected to vibration, silicone must be applied to the glass panels at the upper door rail for added adhesion at the clamped connection! In the case of split door rails (e.g. for a floor lock), align the door rails with the auxiliary cover profile and clamp securely. In order to fix the cover sections, attach the hook end and then tap the cover section home using a wide-area block of wood along the edge (not forgetting the filler profile). (Fig. 3) Fig. 3 DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 2/14 4. Installing the end panel: Slide the upper pivot assembly (a) of the end panel into the end of the track rail. Securely clamp the pivot assembly in position at a distance of 67 mm (between the pivot point and the wall) using a 6 mm Allan key. Install the floor pivot (Fig. 5) or floor spring (BTS) vertically plumb in line with the top pivot assembly axis. In order to be able to hang the end panel, bolt (b) must first be wound down. Next erect the end panel by first inserting bolt (b) into the upper pivot assembly (Fig. 4.1) and then setting the panel down onto the floor pivot or floor spring (Fig. 4.2). After installation, turn bolt (b) until it comes into contact with rollpin (f), then turn it back one revolution for 1 mm clearance; next tighten nut (d) using a 17 mm open-jaw wrench. Then firmly tighten the set screw in the carrier assembly (c) using a 5 mm Allan key. Fix securing plate (e) with bolt (g) onto the upper pivot assembly. (Fig. 4) 4.1 4.2 f a m m b 1 e g 63 d c Fig. 4 67 5. Floor pivot assembly for pivoting end panel: The distance of 63 mm can be achieved/corrected by adjusting the floor pivot (a). Loosen the fixing screws (b), adjust the position of the floor pivot and re-tighten the screws. Adjust the height using the shims (c) provided (3 shims of 1 mm thick each). (Fig. 5) DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 3/14 4 63 c b a 3 Ø 0 1 8 8 S S 40 Fig. 5 Ø 6. Replacing the track rollers: The maintenance end piece (b) can be removed for the replacement of defective rollers (Fig. 6). For this purpose, the pins in the track channel need to be pushed back (using for example a flat tipped screwdriver); the screw must then be loosened and the maintenance end piece can then be withdrawn. When re-installing the maintenance end piece, insert it back into the track run (1), screw fix and then push the pins (2) back across the joint in order to secure the track surfaces and ensure that they are flush (Fig. 6). 100 b 2 1 Fig. 6 DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 4/14 Track roller arrangement: There are four roller arrangements available (Fig. 7) T arrangement: Tandem roller for all automatic-entry stacking tracks. TN arrangement: Low-height tandem roller arrangement (with four reduced-height track rollers) for reshuffle module and niche-type parking/stacking systems. K arrangement: Cross-over roller for all situations involving T and L track fittings. KU arrangement: Cross-over roller arrangement with 90° deflection aid. Fig. 7 T-type roller arrangement TN-type roller arrang. K-type roller arrang. KU-type roller arrang. The arrangement of the track rollers is critical in the diversion area (Fig. 8) A Roller block for straight-through section = high track rollers (a) outside B Roller block for entry into branch section = high track rollers (a) inside a a A B Fig. 8 DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 5/14 7. Threading the panels (Fig. 9): Slide the track rollers with carrier assemblies (a) of all the panels into the track rail. Observe the correct track roller arrangement as described in Section 6! Next place a panel on a 7 mm spacer block on the floor underneath the track rail and insert carriers left and right into the support profile (c). The set screws (c), (Fig. 10) must point outwards. Aligning the panel height: The height of the panels must be aligned to create a 9 mm clearance (without the cover profiles) between the floor and the bottom door rail. Ensure that the top clearance is 33 mm ± 5. If the clearance is greater than 38 mm, reduce the 20 mm glass insertion length in the bottom door rail (lower the bottom door rail). To adjust the height of the panels, loosen nut (d) and adjust the height via nut (e) (using a 17 mm open-jaw wrench). Caution! The set screw (c) must be loosened prior to adjustment as otherwise the pin in nut (a) will shear off. Counter-clockwise rotation = more floor clearance Clockwise rotation = less floor clearance e 35 d 3± c a a 7 9 Fig. 9 DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 6/14 8. Carrier adjustment (Fig. 10): Loosely tighten nut (b), bring the panel into the stacking area, loosen nut (b) and align the panel in the stacking area. Re-tighten the nut and lock with M10 set screw (c) (using 5 mm Allan key). Nut (a) should only be used to adjust the height. a b c Fig. 10 9. Example installation with 4 panels (Fig. 11): P1 = Single action pivoting end panel (PEP) with BTS P2 = Sliding panel (SP) P3 = Sliding panel (SP) P4 = Single or double action pivoting sliding panel (PSP) with ITS Lateral alignment of the panels: Align end panel P1 to provide a 4 mm clearance from the wall (as in Section 5, using nut (d)). Slide the last panel P4 to its end position. Measure the gap from panel P1 to panel P4. (In this example, the gap must be 4 times panel width plus 5 x 4 mm clearance.) (Fig. 11) Fitting the cover profile for the clamp-fit profile: Screw fix a 100 mm end face cover and clamp the cover profiles in position. Then screw fix the second end face cover. Fitting the cover profile for the support profile: Remove the protective film from the Velcro strips. Screw fix a short end face cover to carrier assembly; position and press home the cover section over the support profile starting from the top (Fig. 12). The lock pins for the cover must engage behind the cover (anti-fall protection). (Fig. 12) DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 7/14 PEP SP SP PSP with BTS with ITS 96 1 2 3 4 4 4 4 4 4 1/1 1/2 1/1 Fig. 11 2 1 3 3 3 1 A B Fig. 12 DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 8/14 10. Connection options (Fig. 13): (1) Single action end panel to sliding panel (2) Sliding panel to sliding panel (3) Double action sliding panel to double action sliding panel (4) Sliding panel to double action sliding panel Fig. 13 1 2 3 4 11. Fitting the lock mechanism (Figs. 14 and 15): The top section (a) is supplied already fixed to the track rail. Similarly, the middle section (b) and the bottom section (c) are pre-mounted on the adapter profile and the top door rail respectively. Check that the locking bolt (d) can be screwed easily into the top section (a). If not, loosen screws (e) and re-align the top section (an adjustment of ± 7 mm is possible). The distance (f) must be 3 mm in the case of a single action or double action pivoting sliding panel. ± 7 f 3 . g ax m 65 85.5 95 Fig. 14 DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 9/14 a e b d c Fig. 15 12. Bottom lock (Fig. 16): Position the panel by moving it into its end position and then ensuring that it is properly aligned. Slide the drilling template provided under the lock module and extend the locking pin so that the centre bore can be aligned to its location. Check the position once again and then secure the drilling template (e.g. by holding firmly in position by hand or foot). Retract the locking pin and move the panel away. The position of the eccentric bushing or strike plate can then be properly marked through the drilling template and then the holes can be drilled. Mount the strike plate / keep (eccentric socket) as appropriate. (For exact positioning, strike plate and keep can be adjusted ± 4 mm and ± 2.5 mm respectively.) Then bring the panel into position and lock. Then bring the next panel into position (P3 and P4, leaving a clearance of 4 mm). (Fig. 11) Fig. 16 DORMA-Glas 800.52.119.6.32 Stand/Issue 02/03 Seite/Page 10/14

Description: