Knives 2014: The World's Greatest Knife Book PDF

Preview Knives 2014: The World's Greatest Knife Book

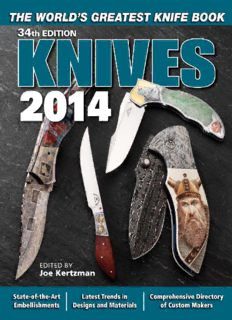

Contents Introduction 2014 Wooden Sword Award Features The Decathlete of Big Blades Climbing Knives Are Heaven Sent Voila! There’s an Art Knife Fueling the Switchblade Obsession! Enjoy an Engraving Tutorial Shopping Mauls? We’ve Got You Covered Blades of the Grand Bazaar Factories Drink from the Custom Maker Well How to Strop a Straight Razor The High Carbon Diet Trends Section Bowies by Many Names Heavy D-Guards An Ultimate Fighting Force Work That Walrus! Dedicated Folders of Fashion Hilts, Boots & Chutes Dimpled, Sculpted, Grooved and Glass Beaded Daggers on Display Bronzed Bodies You’ve Been Lightning Struck! The Tusk at Hand Class “A” Hunters A, B, C’s of Burl Global Arming Molar Knife Caps Bowie Bloodlines Wup, Wup, Wuppa Santoku Style Hot Temper Lines Modern Takes on Tacticals Pick a Peck of Pocketknife Patterns State of the Art Section Whirling-Dervish Damascus Inlays & Etchings Stone Infusion Non-Prosaic Mosaics Sheath Whizzes The Whaler’s Art Full-Length File Work Copious Carving Puzzle Pieces From Under the OptiVisor Pierced Arrows Factory Trends Section Telling the History of America … “One Knife at a Time” Black Blades Abound It’s a Flip Fest Collector Corner Knives Marketplace Directory Custom Knifemakers Knifemakers State-by-State Knifemakers Membership Lists Sporting Cutlers Importers Knifemaking Supplies Mail Order Sales Knife Services Appraisers Custom Grinders Custom Handles Display Cases and Boxes Engravers Etchers Heat Treaters Leather Workers Miscellaneous Photographers Scrimshanders Organizations & Publications Dedication and Acknowledgments Copyright On The Cover Vivid colors leap off the front cover of Knives 2014, and the knives are equally brilliant in hand. Wayne Whittaker’s locking-liner folder at far left features a 3.5- inch Robert Eggerling “armadillos”-mosaic-damascus blade and bolsters, a mammoth-tooth handle exuding blue and red hues, file-worked liners, and zirconia (manmade ruby) inlays in the back spacer and thumb stud. To its right is the “Artiste,” a fascinating little fixed blade—only 6 inches overall—by Don Cowles showcasing a CPM-154 blade, a Pau de Pernambuco (Brazilian violin- bow wood) handle, a 416 stainless steel guard engraved and gold inlaid by Jim Small, 14k-gold pins and a ruby accent on the ferrule. Half folded at top-right lies a Warren Osborne “Ripcord” model called “Rhinos,” parading a Burmese Jadeite handle, a CTS-XHP blade and 416 fittings. Masterful engraving by Tim Adlam, along with inlays of gold, silver and copper, depicts a black rhino on a 24k-gold background on the front bolster, and a Maasai warrior shield on the rear bolster. The reverse side of the knife shows a white rhino and a Swazi warrior’s shield. Peter Carey’s “Rubicon XL” boasts a Chad Nichols “iguana”- stainless-damascus blade, Gibeon-meteorite bolsters, an ivory-inlaid thumb stud and blue-anodized liners. The pre-ban ivory handle is scrimshawed by Gary Williams in a Viking motif, the Viking himself with all the character an artist could conjure upon one knife. All are incredible creations by skilled knifemakers and artists. Introduction A handshake. It tells so much about a person before a word is even spoken. No one should judge a book by its cover—although the Knives 2014 book has a fine one at that—but being perceptive, or interested in someone who extends a hand is perfectly natural and good. A knifemaker’s hand, now that’s a golden glove with stories to tell, isn’t it? Generalizations are rarely advised, but one would rightly expect a bladesmith’s hands to be rough and dirty, a sign of hard work, with lines where metal met tissue, scarred from cuts, soot embedded under the fingernails. Maybe a few nails are broken from wrestling steel, working a grinder or taking a hammer to an anvil. Weather also wreaks havoc on a person’s hands. Days, weeks and months spent in the shop or smithy prematurely age the skin, killing cells and dulling the nerves. Yet the dedicated craftsman labors on into the wee hours of the night when slumber takes hold of less sturdy stock. The hands build something, a useful tool that must withstand rigors of its own, tough cutting media, sinewy fibers, stubborn plastics and knotty pine. Like the knifemaker, the tool has an eventual job to do. Just as in nature, the materials’ circle of life continues. It’s a good metaphor. The bladesmith breathes life into steel, synthetics and natural materials. There is a predestination to build what is useful and necessary. The men and women who choose such a path in life, or are born into it, generally take their craft seriously. There it is, another preconception, but one that is complimentary and backed by fact. It has been this author’s experience that knifemakers take great pride in their work. They are a diligent bunch of perfectionists, hand rubbing steel until it shimmers and oiling wood until every grain has a chance to surface. So what about the fruits of their labor? Turn the pages and look inside. Master craftsmen and women have fashioned some of the finest knives the world over this past year, and hired photographers to capture their work on film or digital pixels, where it has been converted to print and properly attributed. The question often arises, “How does one make a living building knives?” Another popular query the Knives author often receives is: “Don’t you eventually run out of things to say about knives?” The answers in order are, “It’s not easy,” and, “No, never.” That which is never easy is often well worth the wait and worth telling. Take a look at the “Trends” and “State Of The Art” sections toward the middle of the book to see the cream of the knifemaking crop that rose to the top of thousands of images submitted for consideration. Like always, the knives themselves helped determine the trends of the era, and decide what common features knifemakers across the globe are including in their designs and patterns. The “State Of The Art” section is just that, current coverage of the hottest knife embellishments including “Inlays & Etchings,” “Stone Infusion,” “Whirling-Dervish Damascus,” “Non-Prosaic Mosaics,” “Full-length Filework” and “Copious Carving.” Scrimshaw and engraving get their just due, and “Puzzle Pieces,” or knives with several handle pieces put together like jigsaw puzzles, are given prime real estate as well. Handcrafted sheaths round out the artistic offerings and lead into the “Factory Trends” section. A bank of features in the front of the book include articles and color photos covering switchblades, mauls, art knives, “Blades of the Grand Bazaar,” climbing knives and high-carbon steel. Knifemaker Tim Zowada explains “How to Strop a Straight Razor,” knife writer Dexter Ewing tells why “Factories Drink from the Custom Maker Well,” and American Bladesmith Society master smith Wally Hayes hopes you “Enjoy an Engraving Tutorial.” In all, it’s been a busy year in the knife shop, as evidenced by the hands of the maker. They are tough like leather, and convey the character and makeup of the man or woman behind them. That alone is reason to appreciate an extended hand that welcomes you into its world, if only for a time. Joe Kertzman

Description: