Fracture of Polymers, Composites and Adhesives, Second ESIS TC4 Conference on Fracture of Polymers, Composites and Adhesives PDF

Preview Fracture of Polymers, Composites and Adhesives, Second ESIS TC4 Conference on Fracture of Polymers, Composites and Adhesives

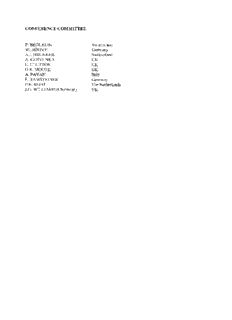

CONFERENCE COMMITTEE .P NILEUG.SIB Switzerland W. BOHME Germany A.J. BRUNNER Switzerland .A CERVENKA UK .E CLUTTON UK D.R. MOORE UK A. PAVAN Italy .F RAMSTEINER Germany P.E. REED The Netherlands J.G. WILLIAMS (Chairman) UK INTRODUCTION It is our pleasure to introduce the proceedings of the Second ESIS TC4 conference which was held in Les Diablerets, Switzerland on 13 ht to 15 ht September 1999. We were gratified by the large number of excellent papers which were submitted. The task of choosing those for presentation and publication was difficult, but the high standard of the presentation and the written versions justifies the choices made. The meeting was designed to reflect the activities of the Committee over the last fifteen years and to look forward to our future activities. We have divided the papers into four chapters under the headings of Composites, Elastic-Plastic Fracture, Adhesion and Impact and General Fracture. This is a convenient grouping, but there are many interactions between the areas, with the common theme of Fracture Mechanics underlying it all. We hope the book is useful and we thank the many authors for their diligence in preparing their contribution. J G Williams A Pavan COMPARISON OF FRACTURE TOUGHNESS (GIc) VALUES OF POLYETHERIMIDE (PEI) AND A CARBON-FIBRE/PEI COMPOSITE: AN EXPERIMENTAL AND THEORETICAL STUDY R. Akkerman, P. E. Reed, K. Y. Huang and L. Warnet Department of Mechanical Engineering, University of Twente. The Netherlands. ABSTRACT GIG values are measured for polyetherimide (PEI) under quasi-static and low speed impact conditions. A novel technique is used to obtain the quasi-static GIG value, based on video-recording of crack growth under test in a single specimen. Further measurements of Gic for a carbon fibre/PEI composite are made, which show greatly reduced fracture toughness of the composite compared to the matrix alone. Causes of the lowered efficiency of translation of the matrix toughness into the composite are explored, using FEA modelling to examine the effects of matrix/fibre interface strength and resin-rich layers on the stress fields in the vicinity of the crack tip. KEY WORDS Fracture mechanics, polyetherimide, thermoplastic matrix composites, INTRODUCTION Thermoplastic matrix, continuous fibre composites have been developed for their toughness and impact resistance. Impact tests on laminate plates fabricated with a thermoplastic matrix generally exhibit less delamination after the test than those made with a brittle thermosetting matrix material. Polyetherimide (PEI) is one of the thermoplastic materials used for thermoplastic matrix composites. In the present work, the particular grade of PEI used is ULTEM | 1000 (GE Plastics). The same grade of PEI is also used by Ten Cate Advanced Composites to produce unidirectional carbon fibre/PEI prepreg material for the manufacture of carbon fibre composite laminates. Carbon fibre reinforcement provides strength and stiffness to the matrix material, but also affects the fracture toughness. This paper first studies the fracture toughness of the ULTEM | 1000 PEI material in isolation and then moves to investigate how the fracture toughness is affected by the introduction of carbon fibre reinforcement in a CF/PEI unidirectional composite containing 60% fibres. All tests used adopt the appropriate ESIS protocol developed for measurement of fracture toughness in thermoplastics and composites. PEI is recognised as a tough but notch sensitive thermoplastic material. The GE data sheet (1) of material properties for ULTEM | 1000 gives Izod impact values of 1300J/m and 50J/m for unnotched and notched PEI specimens respectively, when tested according to the ASTM D256 method (2). These values show how sensitive PEI is to notches or stress concentrations, although the unnotched material is very tough. It should also be noted that the ASTM D256 test method does not provide a fundamental material property value of impact strength, but rather an energy value to break a specific component under test. The component geometry and test conditions are detailed in the standard. 4 .R AKKERMAN, P.E. REED, K.Y. HUANG, L. WARNET QUASI-STATIC DETERMINATION OF THE CIG VALUE FOR PEI The ESIS protocol (3) describes a method for determining the energy release rate under quasi-static loading conditions. Values of CIG so determined are considered as true material property values. The method uses either Single Edge Notched Bend (SENB) or Compact Tension (CT) specimens. SENB specimens have been used in this case. Several beam specimens, each with a different length notch, are tested to failure in 3 point bend using a universal testing machine. The energy (U) required to break each specimen is recorded from the force-deflection diagram. A graph is then made of U against BD~b, the slope of which provides the value of .CIG ,B D and ~bare respectively the specimen breadth, depth and a calibration factor, values for the latter being given in a Table in the protocol. In the present work, 6mm thick sheets of PEI were compression moulded in a closed mould using dried ULTEM | 1000 pellets. Beam specimens were then machined from the plate, with dimensions conforming to the ESIS protocol, 12mm width, 6mm breadth and length of 53mm, using a 48mm length between supports. Notches were then cut and sharpened with a razor blade to give nominal notch depths between 2.5 and 8.0mm in 0.5mm increments. Each specimen was then tested in 3 point bend to failure, measuring the energy to failure in each case. The central deflection was measured directly for improved accuracy, using a Heidenhain electronic micrometer to record the movement of the loading point. After failure, the precise initial crack length was measured from the fracture surface using a travelling microscope. All results were corrected for indentation at the supports, using the method described in the ESIS protocol. 041 021 m 001 E "" 08 ~> ~ o6 w 04 g O2 Z 0 0 5 10 51 20 25 30 5,3 BD~ (mm 2) Figure 1 Energy / BD~ plot from one set of quasi-static tests on PEI. The set comprised 24 specimens, each providing one datum point. Fig.1 shows the energy/BD~ plot obtained from the quasi-static test on PEI which gives a GIG value of 3900J/m .2 The ESIS protocol (3) requires the testing of a minimum of 20 notched specimens, each with a different notch length, to obtain the GIG and CIK values for the material. An alternative approach using only one specimen in conjunction with a CCD camera and timed video recorder, has been explored with the same PEI material. A single SENB specimen was set up in the universal test machine in the 3-point bend test rig as was used for the previous series of tests. An initial razor blade sharpened notch of 2.5mm was made in the single specimen. A CCD camera through a Zeiss microscope was used to monitor the crack growth during the quasi-static test, which was conducted at the recommended speed of 10mm/min. The output from the CCD camera was taken to a video nosirapmoC of Fracture Toughness (Gic) Values... 5 recorder, which had a 25 frames/s recording rate with time display. The load output signal was taken simultaneously through a data logging system to a computer with its associated time base. Hence the computer file held the digitised load/deflection record for the test, recorded at 0.1s intervals as the crack grew. The video recording of the crack growth was analysed using image analysis software, so preparing a record of crack length against time from the start of the test. These data could then be included with the load/deflection record and synchronized to the same time base. This complete file of load/deflection (or energy) against crack length was then processed through the ESIS protocol GIG analysis to generate the usual U against ~qDB data for each increment of crack length. Fig.2 shows the results so obtained from a single PEI specimen. J 8O 6o j 4O 5 10 1E 20 25 30 ~DB mm( )2 Figure 2 Energy/BDq~ plot derived from a video recording of a quasi-static test on a single PEI specimen. The energy/BDq~ data points from the test on the single specimen show very little deviation from the best-fit line, in contrast to data shown in Fig. 1 for multiple specimen testing. The best-fit line for the single specimen data also passes through the origin, suggesting no systematic errors. The value for Gic obtained from Fig. 2 and the single specimen test was 3800J/m ,2 which is comparable with the 3900J/m 2 value obtained from the conventional test which uses a different specimen for each datum point. LOW SPEED IMPACT DETERMINATION OF THE CIG VALUE FOR PEI Further SENB specimens were cut from a cast 6mm thick PEI plate, then notched and prepared in accordance with the ESIS Standard for the determination of CIK and CIG at high loading rates (4). This protocol covers the measurement of the fracture mechanics parameters under impact testing conditions at rates up to l m/s. The high loading rate test method follows the same general analysis as for the quasi-static testing, but includes corrections for the dynamic oscillations in the load/deflection curve. Just enough mechanical damping is used at the point of impact loading to bring the oscillations within limits specified in the protocol. The recorded energy to break under the mechanically load/displacement curve is also determined after applying a computer-aided curve fitting procedure to draw a smooth mean load/time curve through the experimental load/time record. A Dynatup 8250 instrumented falling weight (IFWIM) system was used for the tests. The full series of 20 notched SENB specimens were prepared, with different initial crack lengths inserted and razor sharpened. Overall specimen dimensions were identical to those used for the quasi-static tests. Each specimen was placed in turn in the IFWIM tester and subjected to an impact test at 1.1m/s. It was found that 2 layers of Parafilm were required at the point of impact to achieve the necessary mechanical damping without affecting the maximum force. The load/deflection curves recorded from the IFWIM tests were then processed according to the ESIS protocol, using the prescribed curve 6 .R AKKERMAN, P.E. REED, K.Y. HUANG, .L WARNET fitting routine and checking that the force fluctuations were within the specified 5% limit of the fitted curve. IO0 8o A .__ 40 , - j o ~ ............................... ~ .................................... ; ...................................... ( ................. " ................. ~ .................................. i: :: ---: .......................... -;--: ........................... ---::- 0 5 10 15 20 25 30 35 ~DB mm( )2 Figure 3 Energy/BD~ plot from one set of impact tests of PEI. The set comprised 20 specimens. The value of GIG determined from the 1.1m/s test was 2800J/m ,2 which is considerably lower than the value derived by quasi-static testing of the same material. It would therefore appear that the fracture resistance of ULTEM | 1000 is rate dependent. Frassine and Pavan (5) also observed PEI to be rate dependent, but observed the fracture energy to increase from 2100J/m 2 to 3200J/m 2 over a crack speed range of 6-600mm/min. and at 23~ using Double Torsion specimens. DETERMINATION OF CIG FOR A UNIDIRECTIONAL CARBON FIBRE/PEI COMPOSITE ULTEM | 1000 PEI is used as a matrix material in the production of CETEX | thermoplastic matrix composite laminates manufactured by Ten Cate Advanced Composites. Unidirectional T300-PEI prepreg material is made by drawing the carbon fibres through a bath of PEI dissolved in a solvent to form a continuous sheet of unidirectionally oriented fibres distributed in a matrix of PEI. The prepreg sheet so formed is then dried to remove the solvent, leaving a material with a matrix mass content of 32% (60% fibre volume). The prepreg material is then laid up and pressed to form the required composite laminate. Gic values for the unidirectional T300-PEI material were determined using the test method described in the ESIS protocol for the determination of fracture mechanics parameters for continuous fibre composites (6). Approximately 2mm thick unidirectional T300-PEI laminates were formed from 21 layers of prepreg, pressed in a closed mould at a moulding temperature of 325~ A mt.131 polyimide starter foil was inserted centrally during lay-up, to provide a pre-crack length of 50mm from the edge of the plate in the fibre direction. After pressing, 175mm long, 20mm wide specimens were cut for DCB testing to determine Gic for the unidirectional material. No further preparation of the crack tip was undertaken, thus all GIc values determined relate to cracks initiated from the starter foil. Loading blocks were attached to the ends of the specimens. The DCB specimens were tested at 23~ at a rate of 2mm/min. Two different methods were used to monitor and record the crack growth during the test in relation to the applied load and displacement of the loading blocks. (a) The same CCD camera and timed video recording set up was used as previously described for the PEI specimens. The edges of the DCB specimens were painted with a brittle white paint, which nosirapmoC of erutcarF ssenhguoT )ciG( ...seulaV 7 was then scratched to provide a suitable rule to identify the precise position of the crack tip (and hence the crack length) in the analysis of the video recording after test. (b) The conductive properties of the carbon fibres can also be harnessed to determine the crack length in a DCB test. The change in resistance of the carbon/PEI specimen, measured across the 2 arms of the specimen, can be used to measure the increase in length of the crack throughout the test (7). Crack length determinations using both techniques simultaneously on a specimen are shown in Fig.4. The two techniques provide very close agreement for the increase in crack length with displacement of the loading blocks. The resistance measurement technique records a slightly shorter crack length for a given displacement, leading to a maximum 2.5% variation in the value of GIc determined. Hence both techniques are suitable for the determination of the crack growth during the test. Fig. 5 shows the related force-displacement curve from the DCB test on a T300-PEI specimen. Fig. 6 shows the resulting calculated values of Gic against crack length for the DCB test specimen considered, which were determined using Corrected Beam Theory (CBT) as specified in the ESIS protocol (6). O7 65 .~, ss 114 35 ......... ~ v 30 5 10 15 20 25 30 Displacement )mar( Figure 4. Comparison of crack length determination using the camera method (o) and resistance measurement (,) technique 5O O4 --Z P 3O o 2O 01 0 0 5 01 51 02 25 Displacement )mm( Figure 5. Force-displacement graph of a DCB test on unidirectional T300-PEI 8 .R AKKERMAN, P.E. REED, K.Y. HUANG, .L WARNET 1600 1400 1200 ..-. 1000 800 600 OO4 OO2 0 50 55 60 65 70 75 80 85 90 95 100 Crack length (mm) Figure 6. Crack propagation values of GIG against crack length for the DCB test considered, calculated using Corrected Beam Theory specified in the ESIS Protocol (6) Fig. 6 shows a value of Gic for the T300-PEI of 1200 J/m .2 This value is much lower than those previously discussed from measurements of ciG for PEI alone (3900J/m 2 from the quasi-static testing and 2800 J/m 2 from low speed impact testing). While the fracture toughness of PEI appears to exhibit a rate effect, the inclusion of the carbon fibres greatly reduces the fracture toughness by a factor of 3 over the quasi-static value for the PEI alone. Frassine and Pavan (5) have observed a similar reduction in the fracture toughness of the CF/PEI composite over the pure resin. They measured Gic values for the composite at 23~ which increased with crack speed from 1740J/m 2 at a crack speed of 01 5- m/s to 1900J/m 2 at 10-2m/s at 23~ Crack speeds in the present work were of the order of 3xl 0 2 m/s. While the currently measured GIG value for the T300-PEI is similar to that measured by Frassine and Pavan, it is noticeably lower. The origins of this difference are not known, although results are influenced by variations of the processing conditions used to form the laminates. LOWERED EFFICIENCY OF TRANSLATION OF FRACTURE TOUGHNESS Several workers have observed similar lowering of efficiency of translation of high resin fracture toughness into delamination fracture toughness for the composite (8-10). Yee(8) suggested that the presence of the fibres led to a reduction in the size of the plastic zone at the crack tip. Bradley(9) attributes the lowered efficiency in the tough matrix composites to constraint imposed by the fibres on the development of the plastic zone at the crack tip. Dubois and Keunings(10) performed detailed FE modelling for a unidirectional glass-fibre/poly(arylamide) matrix system DCB specimen, adopting a square array for the fibre distribution. They found that, on planes perpendicular to the crack passing through the fibre axes, the plastic zone was large, extending almost to the surface of the specimen. This contrasted with a small plastic zone in the case of the matrix alone. The overall increase in the plastic zone for the composite led to a reduction of the plastic energy density within the zone and was attributed to the reduced fracture toughness for the composite. In the T300-PEI composite, it is known that the interface bonding of matrix to fibre is relatively poor and also that resin-rich interlaminar layers occur in the fabricated composite. Due to the method of manufacture of the prepreg material, one side of the prepreg contains a thicker layer of the PEI resin than the other. When the multilayer unidirectional laminate is pressed, the resin rich prepreg surfaces can be brought together in the centre, so creating a resin rich layer in the DCB specimen for the crack to follow. These two factors were also noted by Bradley(9), but he suggested that interfacial failure only played a minor role in the reduced fracture toughness of the composite. These two further factors are now explored, to see if they might also contribute significantly to the reduction in fracture toughness of the T300-PEI composite over the pure resin PEI. nosirapmoC of (Gic) Fracture Toughness ...seulaV 9 Fig. 7 shows a SEM photograph of the fracture surface of a DCB T300/PEI specimen. The photograph reveals general poor adhesion between matrix and fibre, with many nearly 'clean' fibres and few with adhering matrix. The crack tends to grow more easily along the fibre-matrix interface. Figure .7 SEM photograph of a carbon-fibre/polyetherimide delamination surface The mechanisms leading to either interface or matrix fracture have been investigated numerically, by considering the stress distribution in the matrix around a single fibre. A detailed account of the analysis is given by Warnet (11) and is only summarised here. The ANSYS finite element package was used to examine the situation around a single fibre near the crack tip of a DCB specimen at the moment of crack initiation. The situation is shown in Fig. .8 Figure .8 Location of the region analysed for the stresses around a single fibre near the crack tip of a DCB specimen. Fig. 8 shows the cross-section A-A with a single fibre oriented in the x direction, located at distance d from the crack plane. Square packing of the fibres is assumed. The quarter fibre with matrix is modelled and the resulting model geometry using 4 noded quadrilateral elements is shown in Fig. .b8 10 .R AKKERMAN, P.E. REED, K.Y. HUANG, .L WARNET The square cell is of unit edge length and the fibre radius is then related to the fibre volume fraction. The 60% volume fraction considered requires a dimensionless radius of 0.874 within a unit square, as indicated in Fig. 8. Material properties of both matrix and fibre used for the calculation are given in Table .1 ~2 /~ /~ T300 230 14 0.2 0.25 0.7xl 0 6- 5.6x10 -6 - Fibre E G GPa GPa /~ ULTEM 56.6x10 6- 1000 Table .1 Thermo-mechanical properties of T300 and Polyetherimide used for the analysis The analysis is performed in two stages. Initially the residual stresses originating from initial fabrication are modelled as the unidirectional composite cools from the fabrication temperature of 325~ to room temperature. The Tg of PEI is quoted as 215~ hence a temperature difference of -193~ is applied in the model for cooling from initial solidification of the PEI to room temperature. A second stage analysis is subsequently applied, in which a unidirectional displacement field yU is applied as indicated in Fig. 8, equivalent to that which occurs in the DCB specimen around the crack tip at the crack initiation condition. This displacement field is extracted from a FEM model of the complete DCB specimen. Fig. 9 shows the nodal displacement field yU obtained from the DCB model as a function of the transverse distance y from the crack tip (from 0 to 1 ply thickness), as well as the longitudinal distance x from the crack tip (from 0 to 0.5mm). Fig.9 shows that the relative nodal displacement rate du/dy is highest near the crack tip due to the singularity at this point. It is also noted that the transverse displacement yu approaches zero at a longitudinal distance of only 0.5mm from the crack tip plane. 3.0E-06 y,~ 2.5E-06 (cid:12)9 (cid:12)9 (cid:12)9 + (cid:12)9 + (cid:12)9 .' t_.~. x (cid:12)9 (cid:12)9 (cid:12)9 + + + (cid:12)9 2.0E-06 4, (cid:12)9 + (cid:12)9 (cid:12)9 + : ,i, + (cid:12)9 + (cid:12)9 + (cid:12)9 x (cid:12)9 x (cid:12)9 x x 4, (cid:12)9 + (cid:12)9 (cid:12)9 x x x x 1.5E-06 (cid:12)9 (cid:12)9 (cid:12)9 + + (cid:12)9 (cid:12)9 + x (cid:12)9 x (cid:12)9 x x x (cid:12)9 + (cid:12)9 x (cid:12)9 + (cid:12)9 x 1.0E-06 (cid:12)9 (cid:12)9 + (cid:12)9 + x (cid:12)9 x (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 + (cid:12)9 x (cid:12)9 (cid:12)9 + (cid:12)9 x (cid:12)9 (cid:12)9 5.0E-07 (cid:12)9 + Ax x (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 (cid:12)9 0.0E+00 (cid:12)9 (cid:12)9 (cid:12)9 - - ~ ~ o _~, ~ o o , 0.0E+00 5.0E-05 1.0E-04 1.5E-04 y(mm) (cid:12)9 x=0 + x=6um (cid:12)9 x=13um x x=21um (cid:12)9 x=100um o x=489um Figure 9. Transverse displacement near the crack tip of a DCB specimen at crack initiation. x( andy are as defined in Fig. 8b. yU is the transverse displacement at a specific x,y) The stress situation around a fibre is considered at an arbitrary longitudinal distance x of 0.1 mm. This leads to a relative nodal dimensionless displacement (uy) of 8xl 0 ~ to be applied to the model shown in Fig.8 to determine the stress distribution in the matrix around the fibre for 2 extreme conditions (a) perfect adhesion between fibre and matrix (b) no interfacial adhesion.