Coke Oven Furnaces Coke Oven - European Environment Agency PDF

Preview Coke Oven Furnaces Coke Oven - European Environment Agency

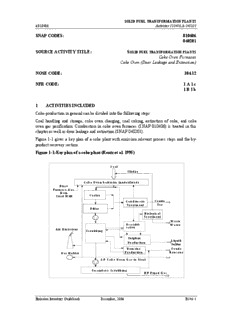

SOLID FUEL TRANSFORMATION PLANTS ic010406 Activities 010406 & 040201 SNAP CODES: 010406 040201 SOURCE ACTIVITY TITLE: SOLID FUEL TRANSFORMATION PLANTS Coke Oven Furnaces Coke Oven (Door Leakage and Extinction) NOSE CODE: 104.12 NFR CODE: 1 A 1 c 1 B 1 b 1 ACTIVITIES INCLUDED Coke-production in general can be divided into the following steps: Coal handling and storage, coke oven charging, coal coking, extinction of coke, and coke oven gas purification. Combustion in coke oven furnaces (SNAP 010406) is treated in this chapter as well as door leakage and extinction (SNAP 040201). Figure 1-1 gives a key plan of a coke plant with emission relevant process steps and the by- product recovery section. Figure 1-1: Key plan of a coke plant (Rentz et al. 1995) Coal Sludge Coke Oven batteries (underfired) Blast Furnace Gas from Steel Mill Cooler Condensate Crude Treatment Tar Filter Biological Treatment Waste Deacidifi- Water cation Air Emissions Scrubbing Sulphur Liquid Production Sulfur Benzene Crude Gas Holder Production Benzene LP Coke Oven Gas to Steel Secondary Scrubbing HP Piped Gas Emission Inventory Guidebook December, 2006 B146-1 SOLID FUEL TRANSFORMATION PLANTS Activities 010406 & 040201 ic010406 2 CONTRIBUTION TO TOTAL EMISSIONS Table 2-1: Contribution to total emissions of the CORINAIR90 inventory (28 countries) Source-activity SNAP-code† Contribution to total emissions [%] SO NO NMV CH CO CO N O NH PM* 2 x 4 2 2 3 OC Coke Oven 010406* 0.5 0.3 0 0 0.2 1.0 - - - Furnaces Coke Oven (Door 040201 0.1 0.1 0.2 0.1 0.5 0.1 -0.1 0.1- - Leakage and Extinction) 0 = emissions are reported, but the exact value is below the rounding limit (0.1 per cent) - = no emissions are reported † = SNAP90 code 030202 * = PM (inclusive of TSP, PM and PM ) is <0.1% of total PM emissions 10 2.5 Table 2-2: Contribution to total heavy metal emissions of the OSPARCOM-HELCOM- UNECE inventory for 1990 (up to 38 countries) Source-activity SNAP-code Contribution to total emissions [%] As Cd Cr Cu Hg Ni Pb Zn Coke Oven (Door Leakage 040201 0.3 1.3 1.3 0.2 1.0 0.1 0.1 0.1 and Extinction) The emissions of persistent organics are also relevant. According to this OSPARCOM- HELCOM-UNECE inventory, coke ovens contributed some 3.1 % to total emissions of PAH in 1990. Coke production is unlikely to be a significant source of sulphurhexafluoride (SF6), hydrofluorocarbons (HFCs) or perfluorocarbons (PFCs), (ETC/AEM-CITEPA-RISOE 1997). 3 GENERAL About 90 % of the coke consumed in the EU is used in pig iron production. The major part is used in blast furnaces, followed by iron foundries, non-ferrous smelters, and the chemical industry. 3.1 Description Coke and coke by-products (including coke oven gas) are produced by the pyrolysis (heating in the absence of air) of suitable grades of coal. The process also includes the processing of coke oven gas to remove tar, ammonia (usually recovered as ammonium sulphate), phenol, B146-2 December, 2006 Emission Inventory Guidebook SOLID FUEL TRANSFORMATION PLANTS ic010406 Activities 010406 & 040201 naphthalene, light oil, and sulphur before being used as a fuel for heating the ovens (World Bank Group 1997). For coke production, hard coal is crushed, mixed and sieved. The coal is transported to the coke oven, which is charged by the mixture. After heating for 14 to 36 hours at 1,150- 1,350°C, in the absence of oxygen, the coked mixture is pressed out of the coke chambers into special wagons. Subsequently, the hot coke will be extinguished. The emissions related to coke production can be attributed to four sub-processes, namely: • Coal handling and storage: emitting coal dust, • Coke production and extinction: emitting coal and coke dust and coke oven gas, • Coke oven gas handling and purification: emitting benzene, toluene, xylene, phenol, PAH, H S, HCN and NH , 2 3 • Combustion of coke oven gas: emitting C H , SO , NO , CO, CO , HF and soot. x y 2 x 2 3.2 Definitions Production of coke: heating of coal mixtures in absence of oxygen at high temperatures Extinction of coke: cooling of the hot coke after removal from the coke-chambers Coke oven gas: the gas formed during coking of the coal 3.3 Techniques In the coke making process, bituminous coal is fed (usually after processing operations, which control the size and the quality of the feed) into a series of ovens. The coke oven itself is a chamber, built of heat resistant bricks, generally 0.4-0.7 m wide, 4-8 m high and 12-18 m long. A chamber has two doors, one at each end, covering almost the full cross-sectional area. In the roof, there are 3-5 charging holes and a gas outlet ("ascension pipe"). Commonly 40 to 70 chambers, alternating with heating walls, form a coke oven battery (Dutch Notes on BAT 1997). Combustion of gases in burners in the flues between the ovens provides heat for the process. In order to improve the energy efficiency, regenerators are located right under the ovens, exchanging heat from flue gases with combustion air or fuel. Coke oven gas from the by-product recovery plant is the common fuel for underfiring the ovens at most plants, but blast furnace gas, and infrequently, natural gas may also be used (US-EPA 1985). The ovens are sealed and heated at high temperatures. The generation of steam, gases, and organic compounds starts immediately after charging and they are exhausted via ascension pipes into the crude gas collecting system (Dutch Notes on BAT 1997). Volatile compounds are processed to recover combustible gases and other by-products. After coking, the vertical doors on each end of an oven are removed, a long ram pushes the coke from the oven into a rail quench car, which goes to a quench tower. There, large volumes of water are sprayed onto the coke mass to cool it, so that it will not continue to burn after being exposed to air. Alternatively, circulating an inert gas (nitrogen), also known as dry quenching can cool it. Coke is screened and sent to a blast furnace or for storage. The raw coke oven gas exits at temperatures of about 760 to 870 °C and is shock cooled by spraying recycled flushing liquor in the gooseneck. This spray cools the gas to 80 to 100 C, precipitates tar, condenses various vapours, and serves as the carrying medium for the Emission Inventory Guidebook December, 2006 B146-3 SOLID FUEL TRANSFORMATION PLANTS Activities 010406 & 040201 ic010406 condensed compounds. These products are separated from the liquor in a decanter and are subsequently processed to yield tar and tar derivatives (US-EPA 1985b, van Osdell et al. 1979). The gas is then passed either to a final tar extractor or an electrostatic precipitator for additional tar removal. When the gas leaves the tar extractor, it carries 75 % of the ammonia and 95 % of the light oil originally present when leaving the oven. The ammonia is recovered either as an aqueous solution by water absorption or as ammonium sulphate salt. The gas leaving the saturator at about 60°C is taken to final coolers or condensers, where it is typically cooled with water to approximately 24°C. During this cooling, some naphthalene separates and is carried along with the wastewater and recovered. The remaining gas is passed into a light oil or benzene scrubber, over which is circulated a heavy petroleum fraction called wash oil or a coal-tar oil, which serves as the absorbent medium. The oil is sprayed in the top of the packed absorption tower while the gas flows up through the tower. The wash oil absorbs about 2 to 3 % of its weight of light oil, with a removal efficiency of about 95 % of the light oil vapour in the gas. The rich wash oil is passed to a countercurrent steam stripping column. The steam and light oil vapours pass upward from the still through a heat exchanger to a condenser and water separator. The light oil may be sold as crude or processed to recover benzene, toluene, xylene, and solvent naphtha (US-EPA 1985b, van Osdell et al. 1979). After tar, ammonia, and light oil removal, the gas undergoes final desulphurisation (e. g. by the Claus process) at some coke plants before being used as fuel. The coke oven gas has a rather high heating value, in the order of 20 kJ/m3 (STP). Typically, 35 to 40 % of the gas is returned to fuel the coke oven combustion system, and the remainder is used for other plant heating needs (US-EPA 1985b, van Osdell et al. 1979). Although most benzene is obtained from petroleum, some is recovered through distillation of coke oven light oil at coke by-product plants. Light oil is a clear yellow-brown oil which contains coal gas components with boiling points between 0 and 200°C. [30] Most by-product plants recover light oil, but not all plants refine it. About 13-18 l of light oil can be produced from coke ovens producing 1 Mg of furnace coke. Light oil itself contains from 60 to 85 % benzene (US-EPA 1985, Loibl et al. 1993). 3.4 Emissions The coke oven is a major source of fugitive emissions into the air. The coking process emits sulphur oxides (SO ), nitrogen oxides (NO ), volatile organic compounds (non-methane VOC x x and methane (CH )), carbon dioxide (CO ), carbon monoxide (CO), ammonia (NH ), 4 2 3 particulate matter, and heavy metals. In general, emissions of nitrous oxide (N O) are not 2 relevant. Coke ovens are an important source of PAH emissions (polycyclic aromatic hydrocarbons). The components of coke oven gas (raw gas) and their concentration can be given as follows. Table 3.1: Composition of raw coke oven gas (Winnacker 1982) B146-4 December, 2006 Emission Inventory Guidebook SOLID FUEL TRANSFORMATION PLANTS ic010406 Activities 010406 & 040201 Components of coke oven gas Concentration [Vol.-%] H 58 - 65 2 CH 24 - 29 4 CO 4.6 - 6.8 CH 2 - 4 n m CO 1.5 - 2.5 2 Besides these compounds, the following by-products are also components of the coke oven gas produced: tar, phenol, benzene, pyridine, ammonia, H S, HCN, CS (carbon bisulphide) 2 2 (Winnacker 1982). The by-product recovery section of a coking plant (e.g. ammonia processing, tar processing) may release significant amounts of NMVOC, CH , NH and 4 3 particulate matter (covered by SNAP code 040201). Furthermore, continuous and discontinuous releases of emissions into the air can be distinguished (Dutch Notes on BAT 1997): Continuous emissions to air: − Emissions from storage and handling of raw materials and products, − Oven door and frame seal leakage, − Ascension pipe leakage, − Charging holes leakage, − Coke oven firing, − Vent systems in gas treatment plant, − Desulphurisation plant. − Discontinuous emissions to air: − Oven charging, − Coke pushing, − Coke cooling. 3.5 Controls Charging: Dust particles from coal charging can be evacuated by the use of jumper-pipe system and steam injection into the ascension pipe or controlled by fabric filters (World Bank Group 1997). Coking: Emissions decrease with the increase of the size of the ovens. Large ovens increase batch size and reduce the number of chargings and pushings, thereby reducing associated emissions. Emissions are also reduced by constant coking conditions, cleaning, and a low-leakage door construction e. g. with gas sealings (Dutch Notes on BAT 1997). Pushing: Emissions from coke pushing can be reduced by maintaining a sufficient coking time thus avoiding the so-called "green push". Fugitive emissions can be controlled by sheds, enclosed Emission Inventory Guidebook December, 2006 B146-5 SOLID FUEL TRANSFORMATION PLANTS Activities 010406 & 040201 ic010406 cars or travelling hoods. Captured gases should be treated in fabric filters (World Bank Group 1997). Quenching: Dry quenching creates lower emissions compared to wet quenching. Gases released from the dry quenching unit can be extracted and filtered. In the case of wet quenching, measures have to be taken to prevent pollutant transfer from wastewater to the air (Dutch Notes on BAT 1997). By-product recovery: In the processing of light oil, tar, naphthalene, phenol, and ammonia vapour recovery systems can be used. Tail gases from desulphurisation (Claus plant) can be returned to the coke oven gas system. Combustion of coke oven gas: Flue gases from coke oven firing contain NO , SO and particulate matter as main pollutants. x 2 SO emissions depend on the degree of desulphurisation of the coke oven gas. NO emissions 2 x may be reduced by low-NO -firing techniques. x 4 SIMPLER METHODOLOGY For the simpler methodology, where limited information is available, default emission factors may be used together with information on coke production in a given country or region without further specification of the type of process technology or efficiency of control equipment. This procedure does not distinguish combustion emissions and emissions from door leakage and extinction. Default emission factors are provided in Section 8.1. N.B There are no emission factors available for PM . The source is <0.1% of the total PM 2.5 emissions for most countries. 5 DETAILED METHODOLOGY The assessment of emissions with the more detailed methodology requires knowledge of the four sub-processes of coke production. If detailed information about the local situation is available this should prevail over the use of default emission factors. Reference emission factors for comparison with users data are provided in Section 8.2. Should a key source analysis indicate this to be a major source of particulate matter (TSP, PM or PM ) then installation level data should be collected using a measurement protocol 10 2.5 such as that illustrated in Measurement Protocol Annex. 6 RELEVANT ACTIVITY STATISTICS Standard statistics on coke production and fuel consumption (e. g. International Energy Agency, United Nations, Eurostat, International Iron and Steel Institute etc.). B146-6 December, 2006 Emission Inventory Guidebook SOLID FUEL TRANSFORMATION PLANTS ic010406 Activities 010406 & 040201 7 POINT SOURCE CRITERIA Integrated iron and steel plants with production capacities of more than 3 million Mg/a have to be treated as point sources according to the CORINAIR90 methodology. Coke oven furnaces included in these integrated iron and steel plants have to be considered as a part of the point source. 8 EMISSION FACTORS, QUALITY CODES AND REFERENCES 8.1 Default emission factors for use with simpler methodology (Source: Pacyna et al, 2002) Pollutant Emission factors Units Arsenic 0.01 g/t coke Cadmium 0.01 g/t coke Chromium 0.15 g/t coke Copper 0.1 g/t coke Mercury 0.01 g/t coke Nickel 0.1 g/t coke Lead 0.25 g/t coke Zinc 0.4 g/t coke 8.2 Detailed methodology In table 8.2a average overall emission factors are presented for coke production. For reference (Emission Registration 1990), emissions due to coke oven gas purification and fuel combustion are included. In the other references from this table it is not clear if fuel combustion is included or not. Emission Inventory Guidebook December, 2006 B146-7 SOLID FUEL TRANSFORMATION PLANTS Activities 010406 & 040201 ic010406 Table 8.2a: Overall emission factors for coke production (g/Mg coke produced) Compound Plant type Emission factor Data Abatement Abatement Fuel type Country or Ref. Quality type efficiency region Particulates All processes 500 - 900 E n. a. n. a. n. a. Germany (Luftreinh. 1989) Particulates All processes 53 E n. a. n. a. n. a. Netherlands (E. Registr. 1990) Particulates All processes 800 - 5000 E n. a. n. a. n. a. USA (US-EPA 1990) VOC All processes 730 - 28002) E n. a. n. a. n. a. Netherlands (E. Registr. 1990), USA (US-EPA 1990) PAH All processes 29 E n. a. n. a. n. a. Netherlands (E. Registr. 1990) B(a)P All processes 0.16 - 0.6 E n. a. n. a. n. a. Germany (Luftreinh. 1989), Netherlands (E. Registr. 1990) Arsenic All processes 0.003 - 0.03, 0.321) E n. a. n. a. n. a. Germany, (Luftreinh. 1989), USA (US-EPA 1990) Cadmium All processes 0.0007 - 0.8 E n. a. n. a. n. a. Germany (Luftreinh. 1989), Netherlands (E. Registr. 1990) Chromium All processes 0.17 - 0.34 E n. a. n. a. n. a. Germany (Jockel W. 1991), Netherlands (E. Registr. 1990) Copper All processes 0.09 - 0.05 E n. a. n. a. n. a. Germany (Jockel W. 1991), Netherlands (E. Registr. 1990) Mercury All processes 0.004 - 0.04 E n. a. n. a. n. a. Germany (Luftreinh. 1989), Netherlands (E. Registr. 1990) B146-8 December, 2006 Emission Inventory Guidebook SOLID FUEL TRANSFORMATION PLANTS ic010406 Activities 010406 & 040201 Table 8.2a (continued): Overall emission factors for coke production (g/Mg coke produced) Compound Plant type Emission factor Data Abatement Abatement Fuel type Country or Ref. Quality type efficiency region Nickel All processes 0.065 - 0.19 E n. a. n. a. n. a. Germany (Jockel W. 1991), Netherlands (E. Registr. 1990) Lead All processes 0.08 - 0.6, 2.851) E n. a. n. a. n. a. Germany (Luftreinh. 1989), Netherlands (E. Registr. 1990), USA (US-EPA 1990) Zinc All processes 0.22 - 0.58, 6.491) E n. a. n. a. n. a. Germany (Jockel W. 1991), Netherlands (E. Registr. 1990), USA (US-EPA 1990) 1) calculated with EPA coke dust profile (US-EPA 1990) 2) expressed as methane Emission Inventory Guidebook December, 2006 B146-9 SOLID FUEL TRANSFORMATION PLANTS Activities 010406 & 040201 ic010406 According to the detailed methodology emissions should be calculated individually for all sub-processes. Emission factors for the process steps listed below are summarised in table 8.2.b In table 8.2c, emission factors are given for the detailed sub-processes for total particulate, NO , SO , CO, VOC and NH as reported in the USA (US-EPA 1985). x 2 3 8.2.1 Coal handling Coal handling consists of transport, pulverising, screening, and blending of several types of coal and storage. Table 8.2 includes factors for emissions of coal dust from the total process of coal handling. 8.2.2 The coking process (without combustion) Emissions during coking operations are caused by the charging of the coal into the ovens, the oven/door leakage during the coking period, and by pushing the coke out of the ovens. In table 8.2, overall emission factors for these activities are presented for VOC, NMVOC and PAH. 8.2.3 Coke oven gas purification The coke oven gas collected from the ovens during the coking process is subjected to various operations for separating ammonia, coke oven gas, tar, phenol, benzene, toluene, xylene, pyridine etc. In table 8.2b, emission factors are given for the purification process of coke oven gas. The numbers are derived from data of a Dutch coke plant (Emission Registration 1992). 8.2.4 Combustion Heat, necessary for the coking process, is generated by gas combustion in the flues between the ovens. Coke oven gas is the common fuel for underfiring the ovens at most plants but other gases (blast furnace gas, natural gas) may be used as well. The combustion also causes emissions. In table 8.2b, emission factors are given for combustion emissions, related to the thermal energy input. B146-10 December, 2006 Emission Inventory Guidebook

Description: