Bimack Grinding Machines Advantages PDF

Preview Bimack Grinding Machines Advantages

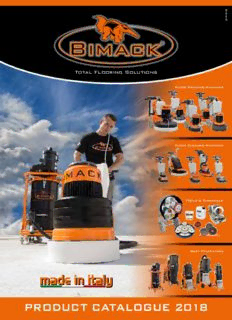

8 1 3 0 1 0 Total Flooring Solutions Floor Grinding Machines Floor Cleaning Machines Tools & Chemicals Dust Collectors PRODUCT CATALOGUE 2018 BIMACK PRODUCT CATALOGUE 2018 Bimack s.r.l. was established with aim of providing innovative TOTALLY MADE IN ITALY products such industrial dust collector, floor grinding & polishing machines, stone & floor care equipments Bimack s.r.l. was founded by a team of leaders with over 20 years experience in the stone processing & floor cleaning equipment manufacturing industry. Bimack s.r.l. produces a wide range of professional and industrial vacuum cleaners, floor care machines, floor grinding and polishing machines for concrete, marble and terrazzo, granite and all kind of natural stones and engineered tiles. In the stone and concrete sector Bimack s.r.l. represents an international reference point thanks to the experience and expertise achieved. Bimack s.r.l. always looks upon technical innovation as the soul of company development. At the heart of establishment lies the concern to deliver innovative product with excellent service. Bimack s.r.l. offers a wide range of products able to cover, with very high quality standards, all the processing phases of stone grinding and polishing surface preparation and polished concrete. The company strives towards technological developments assuring a firm commitment of providing rapid response to customer and long time service to maintain everlasting relationship with customers. Our company is continuously determined to improve and develop our products by investing time and resources in the research and development of new and improved industry technologies. Bimack s.r.l. supplies final users with all the instruments necessary to use its products correctly. It not only offers its advice for all the installation phases, but also trains personnel on request: Bimack s.r.l. provide professional training services how to grind and polish all kind of natural stone & man-made floors and how transform ordinary concrete into a Polished Concrete floor. Bimack s.r.l. has progressively strengthened its network of Assistance Centres trough local dealer in many countries and this process is in continual evolution: the centres ensure punctual interventions to rapidly solve all problems, also thanks to the extremely well-stocked spare parts warehouse at central headquarters. We can proudly say Bimack s.r.l. is the company with core value essence of high quality collection and perfect marketing network, occupying good position in domestic and overseas markets. 2 visit our web site www.bimack.com to view all our full diamond tools range BIMACK FLOOR SYSTEM TRAINING COURSE TO LEARN HOW TO GRIND AND POLISH FLOORS BIMACK provide to you professional training services how to grind and polish all kind of stones and engineered tiles and how to transform ordinary concrete into a glossy Polished Concrete floor. Any contractor, salesperson or distributor interested in receiving the most comprehensive level of training for natural and man-made stones, any contractor who want to learn about Polished and TRAINING Decorative concrete floor system are very welcome at Bimack training courses. COURSE BIMACK can provide to you a full immersion training experience at the Bimack academy classrooms which have been carefully and strategically designed to optimise the learning experience for the students. In addition BIMACK offer to you to send our instructors in your country for a complete and professional training and to support you directly on your job site: our instructors will be able to follow your project floors, to make a full deep train for your polishing team on all different stone processing, to teach how to operate all the machines you have, and complete your jobs with the best result in the short time. Learn about: • Marble and natural Stone Grinding, Restoration and Polishing • Granite Grinding, Restoration and Polishing • Engineered tiles Grinding, Restoration and Polishing • Tile & Grout Restoration • Tile and Grout Cleaning, Sealing and Colour Sealing • Walls and Counter tops Restoration and Polishing • Stone protection, sealing and maintenance • Polished concrete floor • Surface Preparation • Floor Covering Removal Contact us: FAX: +39 085 8599327 MAIL: [email protected] visit our web site www.bimack.com to view all our full diamond tools range 3 BIMACK PRODUCT CATALOGUE 2018 Floor Grinding Machines BK 530 BK 1000 BK 999 BK at-rx-sx series BK propane BK series advanCe BK 580-530 Pag. 14 Pag. 16 Pag. 18-21 Pag. 22-23 Pag. 24-27 Pag. 28 Pag. 29 Single Disc Machines Zperpohpyarnoes Zephyros BK2000 Conan Grinder Conan nextime elmo runner Pag. 51 Pag. 52 Pag. 53 Pag. 54 Pag. 55 Pag. 56 Pag. 57 Pag. 58 Tools and Floor Solutions Floor pads ulutrltarsahlinuex & planetaries easy Kit CroematoinvGe Pag. 72 Pag. 74 Pag. 82 Pag. 84 Pag. 89 Tools and Floor Solutions KinG ConC marBle terraZZo Granite Gres pavelux Pag. 116 Pag. 118 Pag. 120 Pag. 122 Pag. 124 Pag. 126 4 visit our web site www.bimack.com to view all our full diamond tools range BIMACK FLOOR SYSTEM Floor Grinding Machines pBrKo p5a3n0e 800C-h6a5l0le pnrGoerpa ne C8h0a0ll-e7n5G0er C6h5a0ll-e6n0G1er C5h5a1ll-e4n5G1er BK 500-450 BK 430-400 terminator Pag. 30 Pag. 32-33 Pag. 34-35 Pag. 36-37 Pag. 38-39 Pag. 42-43 Pag. 44-45 Pag. 46 Single Disc Machines dexter triple BK BK mini orBit BK orBit asiCnCGelses odriiseCs sKraper 650 Pag. 59 Pag. 62 Pag. 63 Pag. 64 Pag. 66 Pag. 71 Tools and Floor Solutions preFplaoroarti on Bush-hammer supesryCsotenmCrete eliCa superClean Pag. 92 Pag. 98 Pag. 100 Pag. 112 Pag. 114 Tools and Floor Solutions antique FinishinG trapeZoid velCro BaCKed rqeaudiyC KC loooClK & x-line Flash diamond Pag. 128 Pag. 130 Pag. 132 Pag. 136 Pag. 144 Pag. 146 visit our web site www.bimack.com to view all our full diamond tools range 5 BIMACK PRODUCT CATALOGUE 2018 Chemicals polish smaKKio speCials linoleum, pvC Cotto stuKKo Pag. 149 Pag. 150 Pag. 151 Pag. 152 Pag. 153 Pag. 154 Special Machines minipoWer BK quadra BK Wooden Conan sander dexter sander BK mini Wooden rarFatFetre rm t & Pag. 172 Pag. 174 Pag. 178 Pag. 179 Pag. 180 Pag. 187 Pag. 188 Tools for Special Machines mini BK minipoWer BK quadra toWoloso Fdor raFter Pag. 171 Pag. 173 Pag. 175 Pag. 183 Pag. 189 Vacuum Cleaners BloCKduster 90 BloCKduster 77-76-75 BloCKduster 67-66-65 BloCKduster 60 BloCKduster BK11 panda sC 429 drum Pag. 199 Pag. 201-203 Pag. 204 Pag. 205 Pag. 206 Pag. 207 Pag. 208 6 visit our web site www.bimack.com to view all our full diamond tools range BIMACK FLOOR SYSTEM Special Machines vertiKal BK BK super hand BK Counter top Border BaBol mini BK Grinder Pag. 157 Pag. 160 Pag. 164 Pag. 166 Pag. 168 Pag. 170 Tools for Special Machines vertiKal BK BK super hand BKCounter top Border BaBol Grinder Pag. 158 Pag. 161 Pag. 165 Pag. 167 Pag. 169 Dust Extractors BloCpKdroupsatneor 250 BloCKduster 250 BloCKduster 200 BloxC sKderuiesster BloCKduster oil 1B4lo4C-1K5d5u-s1t7er5 BloCKduster 130-140 Pag. 192 Pag. 193 Pag. 194 Pag. 195 Pag. 196 Pag. 197 Pag. 198 Vacuum Cleaners Marketing europa Koala panda meC inox CompaCt pre-separators spare parts marKetinG support Pag. 209 Pag. 210 Pag. 211 Pag. 214 Pag. 218 visit our web site www.bimack.com to view all our full diamond tools range 7 BIMACK PRODUCT CATALOGUE 2018 Bimack Grinding Machines Advantages Motor Engine Motors from 4 to 25 hp even in UL version. High performance. Planetary Head Planetary HEAD that is 100% tempered metal and geared driven not belt. The main disc and the satellites always run, allowing the machine to work very hard with high performance. The working pressure of the Planetary can be adjusted giving pressure on the front or on the backside. Giving more pressure in front the machine cuts faster and deeper. NO BELTS to break! Check what kind of Planetary they are using. The Planetary with BELT DRIVE doesn’t have the same performance of metal geared. Furthermore it is subjected to break during the work and needs a lot of time to repair. Attention: in many machines the main disc and the satellite don’t run together: if you block one satellite (one tools disc by hand) the main disc still runs. It means that using the machine for heavy duty work the machine doesn’t have performance at all. For many machines it is not possible to be used inclined the Planetary and as result can work only in one position. Therefore cannot cut fast and deep resulting in very poor performance. Adjustable working head pressure The pressure is adjusted by “ELECTRONIC DEVICE”. Many machines do not have an ELECTRONIC DEVICE but have to adjust the pressure adding weight manually. Effective weight distribution Bimack design the motor directly over the top of the Planetary with three well balanced heads for perfect balance and highest grinding pressure available. Steel Priority Steel frame painted with metallic varnish. Aluminium carter covering the Planetary. The metal covering protects the diamond tools and allows it to work very close to the wall. Many competitors machines have Plastic coverings. It breaks very easily, it doesn’t protect the diamond tools and doesn’t allow you to work close to the wall. Inverter with Display for fast diagnostics. On the PANEL without opening the Inverter door it is possible to read the display to know what is happening with the machine. Check if this device is on the competitors machine. 8 visit our web site www.bimack.com to view all our full diamond tools range BIMACK FLOOR SYSTEM Third front wheel Third front wheel that offers the following advantages: • It makes for easy transportation. • It allows to regulate the working pressure. • It allows to inclination on the Planetary head. • It is very useful when working on very uneven floors. Check if the competitors machine has the third front wheel. Rigid head for flat floor: The Planetary does not focus weight and pressure of the heads on the chassis to create a ‘floating head’, instead is a rigid system with very little flex (this design means the machine will ‘bounce’ a little over the floor until it is flat). ensures flattest floor possible and doesn’t make the floor ‘wavy’. High tank capacity The tank is very important for working wet. When working dry the diamond doesn’t grip and skates on the surface of the concrete. It is also important for polishing marble, terrazzo and granite. Many competitor machines don’t have a tank. Check and see if it has a water tank. Working Section BK430: Working section 430mm with 3 tools diameter 100mm. BK Attack system. BK450: Working section 450mm with 3 tools diameter 140mm. BK Attack system. BK500: Working section 500mm with 3 tools diameter 200mm. Quick Attack system. Challenger 600: Working section 600mm with 3 tools diameter 240mm. Quick Attack system. Challenger 800: Working section 800mm with 4 tools diameter 240mm. Quick Attack system. BK650: Working section 650mm with 3 tools diameter 240mm. Quick Attack system. BK750: Working section 750mm with 3 tools diameter 240mm. Quick Attack system. BK850: Working section 850mm with 3 tools diameter 240mm. Quick Attack system. BK950: Working section 950mm with 3 tools diameter 340mm. Quick Attack system. Check the size of the tools. Many machine has the same working area but the tools are smaller. Smaller are the tools, less will be the performance. Selector to block the door of the inverter. This device avoids the door from being opened before “switching off” the “electric power”. Strong Antishock System To avoid damage and injury while working in dangerous conditions. visit our web site www.bimack.com to view all our full diamond tools range 9 BIMACK PRODUCT CATALOGUE 2018 Variable speed head that adjusts From 300 up to 1300 rpm Check the speed. Many machine have speed range very limited Dust control Optimized Vacuum ports for working dry and Free of Dust. Check if they have it. Splash Guard Strong Perimetral neoprene splash guard. Check if they have. Remote Control If the machine is equipped with remote control please check the following points: 1. It must be “active system” and not passive system. After an emergency if we push the START BOTTOM the machine does not start the operator has to follow the instructions. 2. If the operator leaves the REMOTE CONTROL the machine stops working avoiding any injuries. 3. Continue Control System. It means: a) A intelligent Remote Control device allowed to check the presence of the operator according the safety rules b) If the operator leaves the device, the remote control stops the machine immediately. c) If the operator leaves the device it cannot be used from any other unauthorized operator to avoid any injuries. d) DEAD MAN SWITCH: all automatic movements are under control by “dead man safety device “in order to work free but in total safety. Safety Rules. satisfy what the SAFETY RULES (Art EN 60204-1 requires) Handle Adjustable position of the handle for a comfortable working position. It also can be reversed to allow the operator to drive the machine from front side and not only from the rear. Many machines cannot be used standing in the front but can be handled only from the rear. 10 visit our web site www.bimack.com to view all our full diamond tools range

Description: