Aquaculture operations in floating HDPE cages PDF

Preview Aquaculture operations in floating HDPE cages

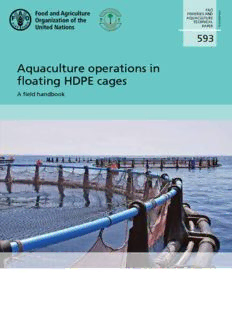

FFAAOO FFIISSHHEERRIIEESS AANNDD ISSNISSN AAQQUUAACCUULLTTUURREE 20 20 77 TTEECCHHNNIICCAALL 0-70-7 00 PPAAPPEERR 1010 559933 Aquaculture operations in floating HDPE cages A field handbook Cover photograph: A floating marine finfish cage farm (Tabuk Fisheries Company) located off the Red Sea coast of Saudi Arabia in the northern coastal province of Tabuk. The HDPE cages are 19 m in diameter and fitted with anti-bird nets (Courtesy Francesco Cardia). Aquaculture operations in FAO FISHERIES AND AQUACULTURE floating HDPE cages TECHNICAL PAPER 593 A field handbook Francesco Cardia FAO Project Manager Kingdom of Saudi Arabia and Alessandro Lovatelli FAO Aquaculture Branch Italy FOOD AND AGRICULTURE ORGANIZATION OF THE UNITED NATIONS(cid:1) and MINISTRY OF AGRICULTURE OF THE KINGDOM OF SAUDI ARABIA(cid:1) Rome, 2015 The designations employed and the presentation of material in this information product do not imply the expression of any opinion whatsoever on the part of the Food and Agriculture Organization of the United Nations (FAO), or of the Ministry of Agriculture of the Kingdom of Saudi Arabia concerning the legal or development status of any country, territory, city or area or of its authorities, or concerning the delimitation of its frontiers or boundaries. The mention of specific companies or products of manufacturers, whether or not these have been patented, does not imply that these have been endorsed or recommended by FAO, or the Ministry of Agriculture of the Kingdom of Saudi Arabia in preference to others of a similar nature that are not mentioned. The views expressed in this information product are those of the author(s) and do not necessarily reflect the views or policies of FAO or the Ministry of Agriculture. ISBN 978-92-5-108749-7 © FAO and Ministry of Agriculture of the Kingdom of Saudi Arabia, 2015 FAO and the Ministry of Agriculture of the Kingdom of Saudi Arabia encourage the use, reproduction and dissemination of material in this information product. Except where otherwise indicated, material may be copied, downloaded and printed for private study, research and teaching purposes, or for use in non-commercial products or services, provided that appropriate acknowledgement of FAO and Ministry of Agriculture of the Kingdom of Saudi Arabia as the source and copyright holder is given and that FAO’s or Ministry of Agriculture’s endorsement of users’ views, products or services is not implied in any way. All requests for translation and adaptation rights, and for resale and other commercial use rights should be made via www.fao.org/contact-us/licence-request or addressed to [email protected]. FAO information products are available on the FAO website (www.fao.org/publications) and can be purchased through [email protected] iii Preparation of this document The document has been funded and produced in the framework of the Technical Cooperation Programme between the Kingdom of Saudi Arabia and the Food and Agriculture Organization of the United Nations during the implementation of two unilateral trust fund projects, i.e. “Support to the Fish Farming Center (FFC), Jeddah, Saudi Arabia” and “Strengthening and supporting further development of aquaculture in the Kingdom of Saudi Arabia”. The purpose of this manual is to provide a general overview of farming and management techniques needed to operate high-density polyethylene (HDPE) floating fish-culture cages, including the types of materials used, their technical specifications and operability. The rationale behind this handbook is to contribute to the capacity building of technical staff on highly practical issues and the management of fish cage farms. Moreover, this publication provides entrepreneurs, managers and workers involved in cage farming with a reference manual where they can find a rich source of technical and biological information, ranging from farm installation to the entire production cycle. The handbook also includes technical tables, logbook examples and functional suggestions acquired from years of field experience, which is shared with the readers. This publication is also addressed to administrations, institutional organizations and development agencies involved in planning, ruling, licensing, subsidizing, etc., with the main practical and technical issues of this relatively new branch of aquaculture being systematically described and explained. Cage aquaculture is nothing but fish production using a (relatively) new technological system. Thus, many of the issues related to fish biology, pathology, feeding, etc., are shared with all other fish production systems. For this reason, the authors have focused as much as possible on practical and operational issues related to cage aquaculture, while readers are referred to more generic literature to obtain in-depth information on other and general aquaculture practices. The handbook briefly covers some important topics such as work safety while others are not dealt with at all (e.g. working boats and cranes, diving technique and equipment) as specific technical competences are required to treat these topics adequately. Finally, procedures and operations described in this manual aim to provide the reader with possible solutions to problems and issues that are usually encountered in the cage farms. Nevertheless, each procedure inevitably needs to be revised and adapted to each site condition, workers’ experience, and the availability of labour, equipment and auxiliary boats. iv Abstract Global aquaculture production has been steadily growing in recent decades, increasingly contributing fish and other edible aquatic organisms of commercial importance entering national, regional and international markets. The growing demand for such products has stimulated the development and expansion of aquaculture production systems both on land and in all waterbodies, covering technologies ranging from the production of seed material to ongrowing structures and other farming support facilities. In recent decades, the aquaculture industry has also intensified its production output per unit area of space or volume, mainly to compensate, among other things, for the growing competition for land and water surfaces for other uses. The expansion of fish farming in the sea, also referred to as “mariculture”, has happened as a result of several supporting factors. These include the acquisition of reproduction and ongrowing technologies for species of interest, and the development of physical structures to contain the cultured organisms. Modern marine cages, whether floating or submersible, represent one such development. These have evolved significantly from basic and rudimental systems to sophisticated and carefully engineered structures. Many cage designs and models have been developed and are commercially available. Among these, high-density polyethylene (HDPE) cages are widely used, because of the versatility of the materials used, the relative simplicity in the performance of the various farming operations, and the comparatively limited investment capital required. Technological improvements of HDPE cages are evolving with the availability of new materials and the various equipment items needed to service all farming operations. This manual focuses on technical aspects of HDPE cages; however, the introductory chapter covers the importance of proper site selection in terms of site exposure and environmental parameters that affect the well-being of the culture fish and affect farm structures. Proper siting of a cage farm is of paramount importance with regard to the overall technical and economic success of the commercial operation, and for reducing as far as possible the environmental footprint of the farm. Prior to describing the characteristics of HDPE cages and elements making up a culture unit, the handbook describes the grid and mooring systems that support the fish cages. Information is provided on the components of the two systems, their technical specifications in relation to farm size as well as on-land assembling and sea installation procedures. A chapter focuses on the floating collar of the cage, describing the components that make up this key farming structure. The technical specifications and design options are provided for the key elements of the collar readily enabling the construction of structures that meet the needs of the operator and are suitable for the environment in which they will be placed. Technical information is then provided on the ropes, netting and net cage design and on determining the appropriate size and shape. Based on procedures developed over years of field experience, practical information on collar and net installation, net changing, maintenance and inspections technique is provided. The final sections of this publication covers practical procedures related to the stocking of cages with seed material, feeding and managing the fish stock, as well as practical information on pre-harvesting and harvesting methods, fish handling and transportation. Some information is also provided on farm safety procedures, highlighting the potential risks when working on a cage farm either on the floating structures or underwater. Cardia, F. & Lovatelli, A. 2015. Aquaculture operations in floating HDPE cages: a field handbook. FAO Fisheries and Aquaculture Technical Paper No. 593. Rome, FAO. 152 pp. v Contents Preparation of this document iii Abstract iv Acknowledgements viii Authors and contributors ix Abbreviations and acronyms xi List of figures xiii List of plates xv List of tables xix 1. Introduction 1 2. Site selection 3 Site selection criteria 5 Environmental criteria for organisms 6 Environmental factors on farmed structures 8 Other criteria 17 Nautical charts 17 Geographical coordinates 17 3. Mooring and grid system installation 19 Navigational buoys 19 Technical characteristics 19 Material assembly on land 20 Deployment 20 Grid system and mooring system 20 Farm footprint 24 Mooring and grid components 25 Mooring system installation 33 4. HDPE cage components 39 HDPE cage characteristics 39 HDPE pipes 39 Brackets 41 Sinkers and sinker tube 44 Collar construction 47 Collar assembly 47 Collar installation 49 Net installation 52 5. Fibres, netting and ropes 55 Fibres 55 Density 55 Polyamide (PA), or nylon 56 Polyester (PES) 56 Polypropylene (PP) 57 High-performance polyethylene (HPPE) 57 vi Ropes 58 Indicative breaking loads and weights of main rope types 58 Netting 58 Net characteristics – material, size, shape and thickness 59 Net cage design 64 Net ropes 65 Seams 67 Net connecters – loops, rings and zippers 68 Net dimensioning 73 Structural details 74 Net treatments – antifouling and UV protection 75 Predator nets 77 6. Maintenance and controls 81 Record-keeping and site plan 81 Logbook 81 Periodic inspections 83 Six-month inspection 83 Mooring lines 83 Marker buoys 84 One-month inspection 84 Marker buoy lights 84 Weekly inspection 84 Grid system 84 Collar and mooring lines 85 Daily inspection 85 Nets 85 Non-conformities 85 Procedures for component replacement 86 Anchor repositioning and mooring line tightening 86 Replacement of a grid-line-to-corner-plate shackle 86 Replacement of buoy-to-corner-plate shackle 87 Replacement of a shackle between chain and buoy 87 Buoy replacement 87 Replacement of a bridle-line shackle 88 Grid line replacement 88 Biofouling removal 88 Cleaning the mooring and grid lines 88 Cleaning the nets 88 Additional suggestions for net cleaning 89 Net changing 90 Preliminary actions in net changing 90 Net detachment 91 Positioning the new net 91 Removal of the fouled net 91 New net attachment 92 Net maintenance on land 93 Net washing machine 93 vii 7. Fish stocking: fingerlings and juveniles 95 Batch quality 95 Fish size 95 Disease 95 Fish number counts 96 Fish inputs 96 Controlled fish output 97 Uncontrolled fish output 97 Fish transport and stocking 97 Plastic bags 98 Cage towing 98 Fish transport tanks 100 8. Fish feeding 103 Feeding systems 105 Hand feeding 106 Feed cannons 106 Automatic feeders 107 Centralized feeding systems 108 9. Fish stock management 111 Biomass monitoring and assessment 111 Tracking cages and cohorts 112 Fish stock report 112 Fish sampling 114 10.Harvesting and packaging 117 Pre-harvest preparation 117 Sampling the fish 117 Starving the fish 118 Preparing the equipment 118 Harvesting methods 118 Purse seine 118 Hand seine net 121 Lift net system 122 Small internal harvest cage 122 Processing and packaging 124 Ice 125 11.Safety notes 127 Scuba diving 128 Safe working load 129 References and further reading 131 Glossary 135 Appendixes 137 Appendix 1 – Technical drawings and component list of a mooring system for a double-buoy cage system, moderate exposure, 16 m diameter cages 139 Appendix 2 – Technical characteristics of netting 145 viii Acknowledgements The preparation of this document has been possible thanks to several experts and institutions that have generously provided their support under different forms. The lead author wishes to thank the Fisheries and Aquaculture Department of the Food and Agriculture Organization for having involved him in several projects on the sustainable development of aquaculture and for having provided guidance and technical advice during all the phases of the preparation of this document. The Government of the Kingdom of Saudi Arabia is duly acknowledged for having financed this publication. The following experts are acknowledged for their valuable contributions: Mr Fabrizio Piccolotti (Cage aquaculture expert), for his inputs in the cage installation, maintenance and harvesting sections of the manual; Mr Alessandro Ciattaglia (Badinotti Group SpA), for his overall revision and expansion of the sections on cage nets, equipment and cage construction and for making available a large number of pictures; Mr Neil Anthony Sims and Mr Michael Bullock (Kampachi Farms), for reviewing and improving the overall publication quality with numerous technical inputs; Mr Stendert Zuurbier (Ad.Aq. Srl) and Mr Fabrizio di Pol (Technosea Srl), for their good suggestions and for making available photographic material; Mr Roberto Có (Aqua Srl), for allowing photographs to be taken in his fish cage farm and used in this publication; Mr Trond Severinsen (AKVA Group ASA), for reviewing and providing further inputs for the finalization of this work; Mr Alessandro Galioto and Mr Stefano Bronchini for allowing photographs to be taken during the fish sampling operations and used in this publication; and Mr Nikos Keferakis for additional photograph material. Thanks are also due to Mr Austin Stankus for proofreading the manuscript. Mr Federico Gemma is acknowledged for the technical drawings included in this publication. Layout design was prepared by Mr Jose Luis Castilla Civit. This work has been possible also thanks to the input of workers and divers who shared their knowledge and experience with the lead author during several years of work in the field. They have made a great contribution with their inventiveness and creativity to the improvement of techniques and procedures for the cage operations.

Description: