150/5320-17 (Part 3) - Appendix 2: Concrete Airfield Pavements - FAA PDF

Preview 150/5320-17 (Part 3) - Appendix 2: Concrete Airfield Pavements - FAA

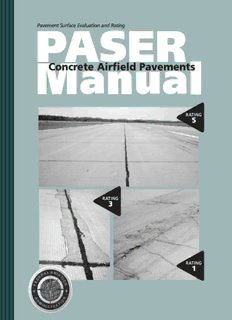

Pavement Surface Evaluation and Rating PASER Manual Concrete Airfield Pavements RATING 5 RATING 3 RATING 1 Contents Introduction 2 Evaluating pavement condition 3 Surface defects 4 Joints 6 Pavement cracks 7 Pavement distortion 10 Rating pavement surface condition 13 Rating system 13 Rating 5 — Excellent 14 Rating 4 — Good 14 Rating 3 — Fair 15 Rating 2 — Poor 16 Rating 1 — Failed 17 Practical advice on rating roads 19 Airfield Pavement Inventory inside back cover This manual is intended to assist airfield managers in understanding and rating the surface condition of rigid Portland Cement Concrete (PCC) pavements. It describes types and causes of distress and provides a simple system to visually rate pavement condition. Produced for the Federal Aviation Administration by Engineering Professional Development, College of Engineering, University of Wisconsin-Madison. AC 150/5320-17 Appendix 2 7/12/04 Pavement Surface Evaluation and Rating PASER Manual Concrete Airfield Pavements Donald Walker, P.E., University of Wisconsin–Madison, author Lynn Entine, Entine & Associates, editor Susan Kummer, Artifax, designer AC 150/5320-17 Appendix 2 7/12/04 PASER — Pavement Surface Evaluation and Rating Concrete Airfield Pavements An airport manager’s goal is to use available funds to provide a safe and economical pavement surface. This is no simple task. It requires balancing priorities and making difficult decisions in order to manage pavements. This manual offers useful information for planning maintenance and managing Portland Cement Concrete (PCC) pavements. It discusses common problems and typical repairs and includes a visual system for evaluating and rating PCC pavements. General aviation airfield pavements are often managed informally, based on the staff’s judgment and experience. While this process is both important and functional, using a slightly more formalized technique can make it easier to manage pavements effectively. Experience has shown that there are three steps that are especially useful in managing airfield pavements: 1) Inventory all pavements. 2) Periodically evaluate the condition of all pavements. 3) Use the condition evaluations to set priorities for projects and evaluate alternative treatments. A comprehensive pavement management system involves collecting data and assessing several pavement characteristics: roughness, surface distress (condition), surface skid characteristics, drainage, and structure (pavement strength and deflection). Planners can combine this condition data with economic analysis, to develop short-range and long-range plans for a variety of budget levels. However, general aviation agencies may lack the resources for such a full-scale system. Since surface condition is the most vital element in any pavement manage- ment system, managers may use the simplified rating system presented in this Concrete Airfield Pavements PASER Manual to evaluate their pavements. A PASER Manual for asphalt airfield pavements is also available (see References, page 20). AC 150/5320-17 Appendix 2 7/12/04 3 Evaluating pavement condition Rigid pavement performance higher edge loads. These higher edge PCC pavement conditions loads can cause further cracking and and defects PCC pavements are either plain (non- deterioration along the joint, or crack reinforced) or reinforced concrete. It is helpful to separate various condi- edges. Reinforcement is usually provided by tions common to PCC pavements. Many concrete pavements use steel wire mesh placed approximately These are described individually in joints that have load transfer dowels. at mid-slab depth. The reinforcement some detail. We include causes for These are smooth steel bars placed is intended to limit crack opening and deterioration and common strategies across the joint. They transfer traffic movement in the concrete slab. Most for repair. Some defects are localized loads between adjacent concrete airfield pavements are not reinforced. while others indicate that problems slabs while allowing the joint to open Since concrete slabs need to move may develop throughout the pave- and close. These bars can rust and (expand and contract) with changes in ment. It is important to distinguish sometimes cause problems. The temperature and during initial cure between local and widespread defects. corrosion causes forces on the (drying and shrinkage), pavements are Assessing the conditions of actual concrete which leads to spalling, constructed with contraction joints. pavements also involves looking for cracking, and general joint deterior- These are usually sawn into the pave- combinations of these individual ation. Epoxy coated dowels may be ment shortly after initial curing. This defects. used to reduce corrosion. joint gives the slab a place to crack and There are four major categories of Unsupported slab edges will deflect makes a straight, well-formed groove common PCC pavement surface or bend under a load. If the support- to seal. Runways, taxiways and aprons distress and condition: ing soil is saturated it can squirt up (ramps) are sawn to create square slabs through joints or cracks when the Surface defects ranging from 15’ to a maximum of 25’. slab bends. This is called pumping. Polishing, map cracking, pop-outs, Isolation joints are occasionally Eventually the loss of supporting soil scaling, spalling. provided. These are wider, full depth, through pumping creates an empty Joints and filled with a material to allow space or void under the slab. The Longitudinal and transverse joints. expansion. If used, they are placed slabs may then crack further under adjacent to structures that cannot move Pavement cracks loads and joints will deteriorate more. with the pavement such as buildings, Slab cracks, D-cracking, corner Undoweled joints under heavy manholes, and other utility structures. cracks, meander cracks, manhole traffic may fault. This is when one These isolation joints are also used at and inlet cracking. slab edge is lower than the next slab. pavement intersections and allow Faulting is more likely on pavements Pavement distortion changes in joint patterns. with most of the traffic in one Pavement settlement or heave; Rigid, PCC pavements carry traffic direction. The downstream traffic slab blow ups; faulting; utility repairs, loadings differently than flexible will be lower than the upstream slab, patches and potholes. pavements (asphalt). Concrete pave- creating a step. Faulting creates a In reviewing the different defects ments are designed to act like a beam rough pavement. it is important to consider both their and use the bending strength of the You can often detect pumping by severity and extent. Generally, condi- slabs to carry the load. Therefore, load the soil stains around pavement joints tions begin slowly and progressively transfer across cracks and joints is or cracks. The resulting voids can be become more serious. Slight defects important, especially on pavements grouted full or sub-sealed. Slabs can may grow into moderate and then with heavy traffic loading. Hairline and be leveled by slab jacking or mud severe conditions. In addition, defects narrow cracks still have interlocked jacking. Obviously, sealing cracks and might initially be indicated only in a concrete aggregate and can effectively joints and improving subsoil drainage few isolated cases. Examples in the transfer loads. Because wide cracks will help reduce pumping, faulting, rating section will help identify how and widely-spaced joints open up, they and joint failures. bad and how extensive a condition is. cannot transfer loads and must take AC 150/5320-17 Appendix 2 7/12/04 4 EVALUATION — Surface Defects ▼ SURFACE DEFECTS Close-up of a polished pavement surface. Polishing A worn or polished surface may develop from traffic wearing off the surface mortar and skid-resistant texture. An asphalt overlay or grinding the concrete surface can restore skid resistance. Map cracking A pattern of fine cracks usually spaced within several inches is called map cracking. It usually develops into square or other geometrical patterns. Map cracking can be caused by improper cure or over- working the surface during finishing. It may also indicate a problem with the quality of the aggregate known as ASR (alkali-silica reactivity). If ▼ severe, cracks may spall or the Map cracking surface may scale. Repair is usually has hairline surface cracks, limited to very severe conditions. probably An asphalt overlay or partial depth shallow in patching may then be necessary. depth. May not cause any Pop-outs long-term performance Individual pieces of large aggregate problems. may pop out of the surface. This is often caused by chert or other absorbent aggregates that deterio- rate under freeze-thaw conditions. ▼ Pop-outs alone do not usually affect Several pavement serviceability. However, pop-outs damage to aircraft from the debris in a new may occur. For severe areas, a slab. patch, overlay or slab replacement may be necessary. ▼ Extensive pop-outs of large aggregate from surface. AC 150/5320-17 Appendix 2 7/12/04 EVALUATION — Surface Defects 5 Scaling Scaling is surface deterioration that causes loss of fine aggregate and mortar. More extensive scaling can result in loss of large aggregate. The cause often is using concrete which has not been air-entrained, making the surface susceptible to freeze-thaw damage. Scaling can occur as a general condition over a large area or be isolated to locations where poor quality concrete or ▼ ▼ Moderate surface improper finishing techniques caused Slight scaling. scaling. Loss of loss of entrained air. In severe cases, Minor loss of mortar and fines deterioration can extend deep into the surface mortar. starting to expose concrete. Debris from scaling can larger aggregate. damage aircraft. Grinding may remove poor quality ▼ Severe surface concrete. Partial depth patching scaling. of isolated areas may also prolong the Some larger life of the pavement. Severe scaling may aggregate is require slab replacement. loose. Spalling Spalling is the loss of a piece of the concrete pavement from the surface or along the edges of cracks and joints. Cracking or freeze-thaw action may break the concrete loose, or spalling may be caused by poor quality mate- rials. Spalling may be limited to small ▼ pieces in isolated areas or be quite Small deep and extensive. Large pieces of surface spall that has loose concrete can cause serious been damage to aircraft. patched. Repair will depend on the cause. Small spalled areas are often patched. Spalling at joints may require full depth joint repair or full slab replacement. ▼ Spall at crack. Creates dangerous debris. ▼ Spalling along a joint. AC 150/5320-17 Appendix 2 7/12/04 6 EVALUATION — Joints JOINTS Construction joints or sawn joints are narrow and usually well sealed. As pavements age and materials deteriorate, joints may open wider and deteriorate further. Cracks parallel to the initial joint may develop and accelerate into spalling or raveling. Settlement, instability, or pumping of subgrade soil can cause joints to fault. One common cause of cracks parallel to joints is waiting too long after the pour to saw the joint. Then, during initial cure the slab will crack near the sawn joint. Maintaining a tight joint seal can prevent intrusion of water and debris and reduce freeze-thaw damage and pumping. Debris may accumulate in open joints which prevents normal joint movement. This will greatly accelerate joint deterioration. Severe ▼ New pavement with good joints. ▼ Joint sealant deterioration on apron. joint deterioration may require full Slab is in good condition. depth patching and joint replacement. ▼ Taxiway with spalled joint. ▼ Joint sealant in poor ▼ Severe spalling condition. Loss of along joint and bond to edge allows crack. Creates debris. water into pavement. AC 150/5320-17 Appendix 2 7/12/04 EVALUATION — Cracks 7 PAVEMENT CRACKS Slab cracks Slab cracks divide the slab into 2 or more pieces. They can be caused by thermal stresses, poor subgrade support, or heavy loadings. They are sometimes ▼ related to slabs with joints spaced too Hairline slab crack. widely. Slabs with a length-to-width ratio Tight with no spalling. greater than 1.25 are more likely to develop mid-slab cracks. ▼ As with joints, these cracks may deteri- Crack next to joint often orate further if not sealed well. Slabs caused by late sawing. Crack shows early signs of spalling. can fault at cracks. Cracks can spall and develop additional parallel cracking. Severe deterioration may require patching individual cracks. Multiple Slab crack with grass, transverse cracks in individual slabs no sealant, and spalls indicate further deterioration. Extensive developing. slab cracking indicates pavement failure ▼ and the need for complete replacement. ▼▼ Slab crack with spalling and debris. Multiple slab cracks and broken pavement. Replacement needed. ▼ ▼ Closely spaced, hair-line, transverse cracks indicate slab is broken and needs replacing. AC 150/5320-17 Appendix 2 7/12/04 8 EVALUATION — Cracks D-cracks Surface discoloration near joints Occasionally, severe deterioration may and cracks indicates D-cracking develop from poor quality aggregate. and severe slab deterioration. So called D-cracks or disintegration ▼ ▼ cracking, develop when the aggregate is able to absorb moisture. This causes the aggregate to break apart under freeze-thaw action which leads to deterioration. Usually, it starts at the bottom of the slab and moves upward. Fine cracking and a dark discoloration adjacent to the joint often indicate a D-cracking problem. Once this is visible on the surface the pavement material is usually severely deteriorated and complete replacement is required. Joint or crack sealing helps slow D-cracking deterioration. This is a serious defect because it may indicate a material quality problem throughout the pave- ment. Milling and patching has proven successful as a short term repair. ▼ Multiple crack patterns adjacent to joints. Common D-cracking pattern. ▼ Corner cracks Corner cracking Diagonal cracks may develop near the with corner of a concrete slab, forming a slight triangle with the joint. Usually these spalling. cracks are within a foot or two of the slab corner and are caused by insufficient soil support or concentrated stress due to temperature-related slab movement. The corner breaks under traffic loading. They may begin as hairline cracks. Some corner cracks extend the full ▼ depth of the slab while others start at the Corner surface and angle down toward the joint. cracking, With further deterioration, more cracking severe spalling, develops, and eventually the entire and broken area may come loose. This may dangerous be a localized failure, but it often debris. indicates widespread maintenance problems. ▼ Corner cracking in Partial or full depth concrete patching all four slabs. or full depth joint replacement may be needed when corner cracking is extensive.

Description: